RA Power Solutions was approached by a leading shipping company based in Athens Greece for the repair of two crankpins that were reportedly damaged due to an accident. Two of the RA Power Solutions technicians boarded the vessel at Chennai port India and inspected the crankshaft of Yanmar Engine 8N280L having the following details.

| S. NO | Crankshaft Details | |

| 1. | Engine Make | Yanmar |

| 2. | Engine Model | 8N280L |

| 3. | Crankpin Diameter Standard | 225 mm |

| 4. | Crankpin Bearing Width | 93 mm |

| 5. | Place of Execution of Job | Sailing from Chennai Port in India to Port of Klang Malaysia |

Details of Inspection of Yanmar Engine 8N280L crankshaft undertaken by RA Power Solutions technicians on board the vessel.

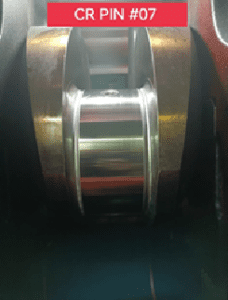

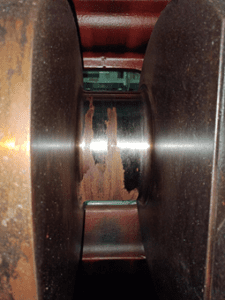

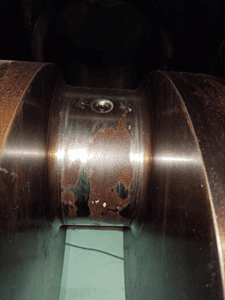

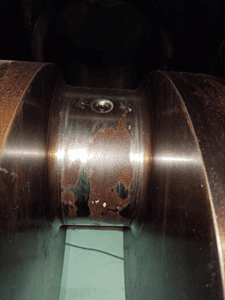

- The vessel reported damage to two crankpins due to the failure of the oil pump initially two crankpins were inspected and ovality ranging from 0.23 to 0.30 mm was found.

- Since it was a failure of lubricating the oil pump decision was taken to open the connecting rods of the remaining six crankpins and inspect them by taper & ovality.

- On inspection of the remaining six crankpins, it was observed that all the crankpins had excessive ovality higher than the permissible limits stipulated in the Yanmar Engine manufacturer manual.

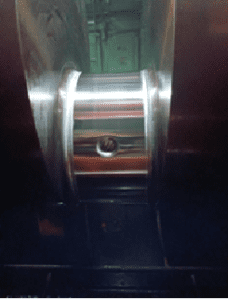

- The bearing line marks a rough surface was also observed.

- The hardness was checked with the portable hardness tester and was observed within limits except for the few scattered high hardness spots.

- MPI for crack detection was also done and no cracks were observed.

- The radius fillet of all eight crankpins was checked.

- In case two crankpin radius fillet profiles were damaged. The reading observed of eight crankpins before grinding is as follows.

SIZE OF CR JOURNAL BEFORE GRINDING SIZES IN MM

| A | Aa | C | Cc | B | Bb | Min | STD | Ovality | |

| CR-1 | 224.77 | 224.93 | 224.76 | 224.90 | 224.78 | 224.80 | 224.76 | 225.00 | 0.24 MM |

| CR-2 | 224.79 | 224.86 | 224.78 | 224.83 | 224.77 | 224.85 | 224.77 | 225.00 | 0.23 MM |

| CR-3 | 224.77 | 224.87 | 224.75 | 224.90 | 224.76 | 224.92 | 224.75 | 225.00 | 0.25 MM |

| CR-4 | 224.78 | 224.91 | 224.74 | 224.88 | 224.76 | 224.89 | 224.74 | 225.00 | 0.26 MM |

| CR-5 | 224.75 | 224.80 | 224.74 | 224.90 | 224.75 | 224.86 | 224.74 | 225.00 | 0.26 MM |

| CR-6 | 224.77 | 224.92 | 224.79 | 224.89 | 224.75 | 224.88 | 224.75 | 225.00 | 0.25 MM |

| CR-7 | 224.76 | 224.92 | 224.70 | 224.90 | 224.77 | 224.86 | 224.70 | 225.00 | 0.30MM |

| CR-8 | 224.78 | 224.91 | 224.76 | 224.90 | 224.77 | 224.89 | 224.76 | 225.00 | 0.24 MM |

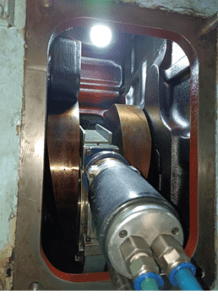

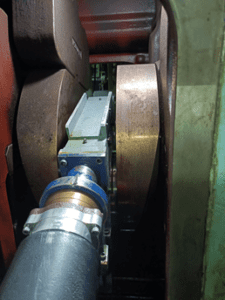

Action taken by RA Power Solutions technicians to repair the crankshaft of Yanmar Engine 8N280L is as follows:

- All the crankpin grinding was undertaken to the first under the size of minus 0.50 mm.

- The tolerance of diameter was maintained as mentioned in the manual.

- The radius fillet profile of two crankpins was corrected.

- The final dimensions after grinding are as follows:

| SIZE OF CR JOURNAL AFTER GRINDING SIZES IN MM | |||||||||

| A | Aa | C | Cc | B | Bb | Min | Max | Ovality | |

| CR-1 | 224.48 | 224.49 | 224.48 | 224.48 | 224.50 | 224.48 | 224.48 | 224.50 | 0.02 MM |

| CR-2 | 224.48 | 224.48 | 224.49 | 224.48 | 224.49 | 224.50 | 224.48 | 224.50 | 0.02 MM |

| CR-3 | 224.49 | 224.49 | 224.48 | 224.50 | 224.49 | 224.49 | 224.48 | 224.50 | 0.02 MM |

| CR-4 | 224.48 | 224.50 | 224.49 | 224.49 | 224.48 | 224.50 | 224.48 | 224.50 | 0.02 MM |

| CR-5 | 224.49 | 224.48 | 224.50 | 224.48 | 224.49 | 224.48 | 224.48 | 224.50 | 0.02 MM |

| CR-6 | 224.48 | 224.50 | 224.49 | 224.48 | 224.49 | 224.49 | 224.48 | 224.50 | 0.02 MM |

| CR-7 | 224.49 | 224.49 | 224.48 | 224.50 | 224.48 | 224.49 | 224.48 | 224.50 | 0.02 MM |

| CR-8 | 224.48 | 224.50 | 224.48 | 224.48 | 224.50 | 224.48 | 224.48 | 224.50 | 0.02 MM |

Achievement of RA Power Solutions technicians in the successful repair of the Crankshaft of Yanmar Engine 8N280L while sailing

The vessel after discharging the cargo at Chennai port left for Port Klang Malaysia. The technicians worked nonstop and completed the grinding of all eight crankpins including the formation of radius fillets while sailing.

Our equipment for onsite crankshaft grinding is designed to absorb the vibration during the sailing of a vessel with RA Power Solutions technicians and equipment on board the vessel there is no need to hold the vessel.

We have been regularly executing on site crankshaft repairs and crankshaft grinding in Dubai, Oman, Saudi Arabia, Qatar, Abu Dhabi, Sharjah, Ajman, Umm Al-Quwain, and Fujairah, Bahrain, Kuwait, Iraq, Antigua and Barbuda, Belize, Dominica, Dominican Republic, Grenada, Guyana, Haiti, Jamaica, Saint Kitts and Nevis, Saint Lucia, Saint Vincent and the Grenadines, Trinidad, and Tobago, etc.

For more details on the crank pin grinding repair please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.