Turbine Shaft Grinding

RA Power Solutions specializes in turbine shaft grinding, a critical process in the field of power generation and industrial machinery maintenance. Turbine shafts play a vital role in the functioning of turbines, ensuring the smooth and efficient conversion of energy. Over time, wear and tear, as well as other operational factors, can lead to imperfections on the surface of the turbine shaft, impacting its performance.

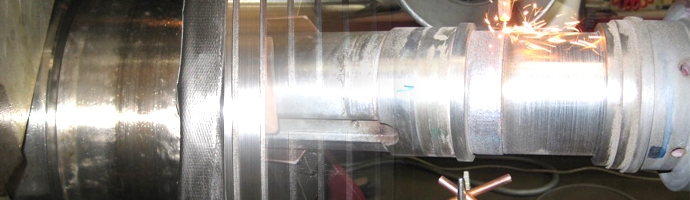

Turbine shaft grinding is a precision machining process offered by RA Power Solutions to restore the integrity and functionality of turbine shafts. The company employs advanced grinding techniques and state-of-the-art machinery to achieve the highest level of precision and accuracy in the grinding process. This meticulous approach is crucial to ensuring that the turbine shaft meets or exceeds the original equipment manufacturer’s (OEM) specifications.

The process typically begins with a thorough inspection of the turbine shaft to identify any defects, irregularities, or damage on the surface. RA Power Solutions’ skilled technicians use specialized equipment to measure and assess the condition of the shaft. Once the assessment is complete, the grinding process begins.

We utilize cutting-edge in situ grinding machines and tools designed specifically for turbine shafts. These machines are equipped with advanced features to achieve precise material removal while maintaining the required surface finish. The grinding process is carried out with the utmost care and attention to detail to ensure that the final product meets the stringent quality standards set by the industry.