crankshaft

30 Mar , 2024

0 Comments

RA Power Solutions received a distress call from a shipping company based in Singapore, informing about the failure of the main engine. The vessel was stranded in Freetown Port, Sierra Leone, Africa. RA Power Solutions immediately sent two technicians with necessary instruments and tools to the Freetown Port, Sierra Leone, Africa, upon receiving a call from the shipping company.

Since the onsite crankshaft grinding equipment used by RA Power Solutions is lightweight and compact, the equipment, along with necessary instruments, was sent with the technician as accompanying baggage. Hence, no time was wasted in the transportation of the equipment and technicians to Freetown Port, Sierra Leone. Upon the arrival of our technician on board the vessel, the following main observations were made.

S. No.

Crankpin Details of Sulzer (Main Engine) 6ZAL40S

1.

Engine Make

Sulzer (Main Engine)

2.

Engine Model

6ZAL40S

3.

Crankpin Diameter Standard

350.00 MM

4.

Crankpin Bearing Width

132.00 MM

5.

Place of execution of grinding of crankpins

Freetown Port, Sierra Leone (Africa)

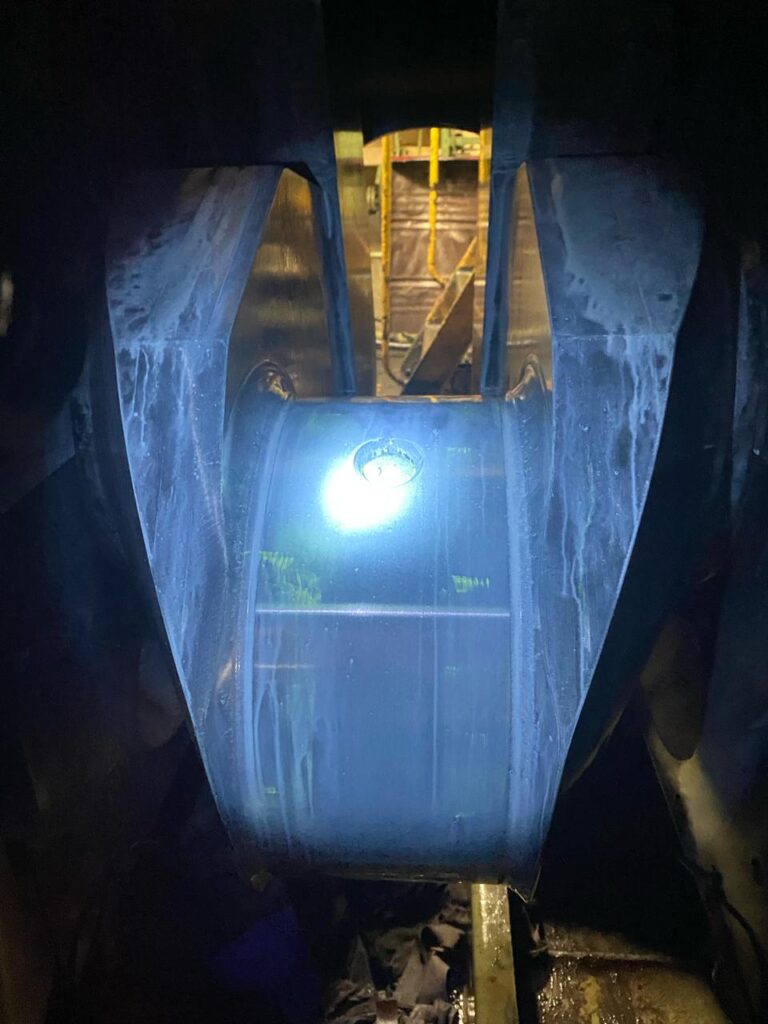

- Crankpin number 1 of the Sulzer (Main Engine) 6ZAL40S was observed to be damaged due to a seizure. The crankpin bearing melted and became embedded on the surface of the crankpin. After the removal of the bearing material, the crankpin was subjected to dimensional inspections. An ovality of 0.38 mm was observed.

- During visual inspections, damage to the radius fillet profiles on both sides due to bearing seizure was observed.

- Local depression or damage on the crankpin surface was also observed, but it was not possible to measure.

- The hardness test was undertaken, and higher hardness was observed, which was scattered and did not form a continuous pattern.

- The crack detection by the MPI method was undertaken repeatedly. We used a high-intensity magnaflux torch, and no cracks or abnormalities were observed.

- All the important parameters, such as deflection and runout, were observed within a limit.

The action was taken by RA Power Solutions for the successful repair of the crankpin of the Sulzer (Main Engine) 6ZAL40S.

- In the case of the Sulzer (Main Engine) 6ZAL40S crankshaft, the manufacturer has specified a 1st step size of -0.40 mm, a second step size of 0.80 mm, and so on.

- Due to localized depression and damage to the crankpin, RA Power Solutions technicians undersized the crankpin to 1.20 mm. This was done as per the manufacturer’s recommendation and tolerances stipulated in the maintenance manual.

- Incidentally, the vessel was carrying a 1.20 mm undersize crankpin bearing, and the engine was assembled.

- The satisfactory performance was observed after the crankshaft repair. The sea trial was also undertaken in the presence of our technicians.

- The detailed inspection report was prepared and can also be shared with our readers/clients.

We have been regularly providing crankshaft grinding repair and crankpin bearing services in Iraq, Iran, Dubai, Oman, Saudi Arabia, Singapore, Russia, Qatar, Abu Dhabi, Sharjah, Ajman, Umm Al-Quwain, Fujairah, Bahrain, Gambia, Kuwait, Antigua and Barbuda, Belize, Dominica, Dominican Republic, Malaysia, Indonesia, Madagascar, Vietnam, Grenada, Guyana, Haiti, Jamaica, Saint Kitts and Nevis, Saint Lucia, South Korea, Saint Vincent, and the Grenadines, Trinidad, and Tobago, etc.

For more details regarding crankshaft machining and grinding, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.