RA Power Solutions was approached by a leading refinery based in the central part of India regarding the breakdown of the crankshaft of their air compressor.

The compressor details are as follows:

| S. NO | Details | |

| 1. | Manufacturer of Compressor | BPCL |

| 2. | Compressor Model No. | 20-KA-RP-102A |

| 3. | Crankpin Standard Diameter | 330 mm |

| 4. | Crankpin Bearing Length 200 mm | 200 mm |

RA Power Solutions team of two technicians visited the plant and an inspection in detail was conducted.

Following are the main observations of the compressor crankshaft of BPCL model 20-KA-RP-102A

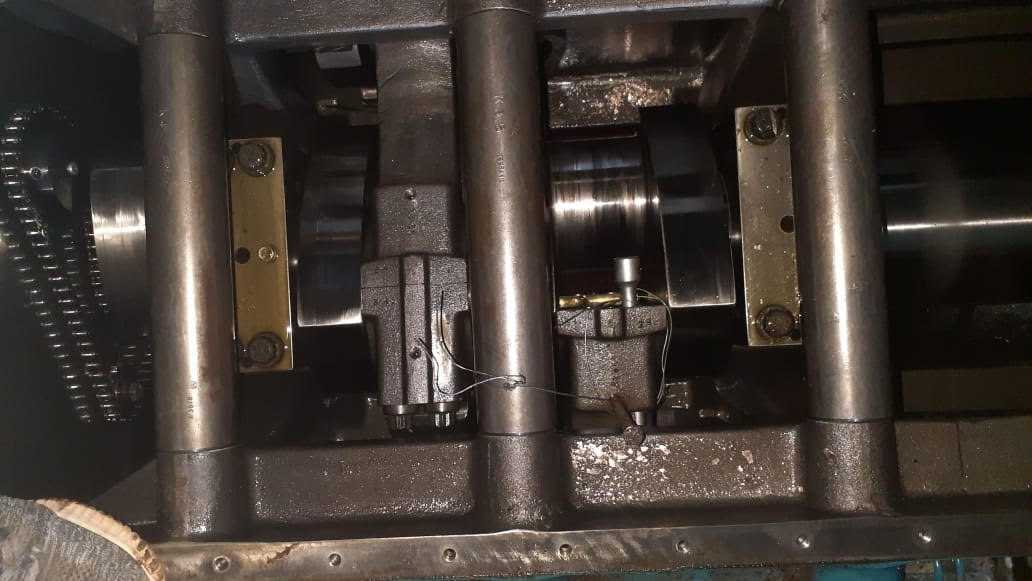

- The compressor crankpin no. 3 bearings were badly damaged due to the seizure of the bearing. The bearing white metal was stuck on the crankpin.

- The seizure of the white metal bearing of crankpin no.3 was so serious that the crankpin bearing was to be removed by use of a hammer and chisel.

- The white metal from the crankpin was removed to undertake the inspection.

- The crankpin no. 3 After the removal of white metal and proper cleaning was subject to dimensional inspection for taper and ovality.

The following Table Shows the Dimensions of Crankpin No.3

| STANDARD/SPECIFIED 330 MM | SIZES IN MM | ||||||||

| SIZE OF CR Pins | |||||||||

| A | Aa | C | Cc | B | Bb | Min | Max | Ovality | |

| CR-3 | 329.95 | 329.81 | 329.94 | 329.78 | 329.9 | 329.57 | 329.57 | 329.95 | 0.38 |

- Since the bearing got seized on the crankpin, deep bearing line marks and depression were observed on the crankpin.

- The crankpin no. 3 was subject to crack detection by a magnetic particle instrument using the high-intensity magna flux torch. No cracks were observed except for a few hairline surface cracks.

- Hardness was checked by a portable hardness tester and was observed within limits except few scattered spots where the hardness was on the higher side. With our experience in the field of repair of compressor shafts these scattered higher hardness spots are ignored.

- The deflection of the compressor crankshaft was checked and was observed within limits which interprets that there is no loss of alignment of the crankshaft and its centerline is not disturbed.

Repair of BPCL compressor model 20-KA-RP-102A crankshaft compressor undertaken by RA Power Solutions

- The grinding of crankpin no. 3 was undertaken and the crankpin size was maintained between 329.40 to 329.42 mm.

- The ovality of 0.02 mm was maintained.

All other parameters like hardness and cracks were checked again and observed within limits. The final dimensions of crankpin no.3 maintained after grinding are mentioned below.

| STANDARD/SPECIFIED NO. | SIZES IN MM | ||||||||

| SIZE OF CR Pins | |||||||||

| A | Aa | C | Cc | B | Bb | Min | Max | Ovality | |

| CR-3 | 329.4 | 329.4 | 329.4 | 329.4 | 329.42 | 329.41 | 329.4 | 329.42 | 0.02 |

Rebabbitting of white metal compressor Crankshaft bearing

- The damaged and badly seized crankpin no. 3 white metal Babbitt bearings were sent to our works immediately upon the arrival of our technicians at the site.

- The Rebabbitting of white metal crankpin no. 3 bearing was undertaken and was kept ready.

- The final machining of the white metal Babbitt crankpin bearing was done according to the size of the crankpin after grinding and the bearing was assembled.

- In this case, all the actions right from inspection, repair of compressor crankshaft, and Rebabbitting of crankpin bearing were monitored closely. The repairs were executed in a short time duration of 3 days. The compressor and the plant were put back into operation in the minimum possible time reducing the losses considerably.

RA Power Solutions has been extending services onsite for repair of compressor shaft, pump shaft, cylinder shaft, grinding of compressor shaft, etc.

We regularly work on all makes and types of Compressor Crankshafts. A few of them are mentioned below:

- Ariel

- Cummins

- Kirloskar

- Samson

- Porter-Cable

- Stanley-Bostitch

- Campbell Hausfeld

- DeWalt

- Makita

- Senco

- ANEST IWATA

- Gardner Denver

- Graham Sulzer

- Hitachi

- Bostitch

- Rolair Systems

- Brehob

- Lufkin

- Zebra

- Ingersoll Rand

- Grasso

- Reciprocating

- Rotary Screw

- Centrifugal

- Gas

- Positive Displacement

- Liquid Ring

- Screw

- Scroll

- Dynamic

- Centrifugal

This blog is written by Mr. Raj Shahani (Managing Director of RA Power Solutions India Pvt. Ltd.). He is a highly experienced business leader with rich experience of more than 43 years in the field of Power, Heavy, and Shipping industry. He is a Technical Adviser to many shipping and heavy industries across the globe.

For more information on grinding of compressor shaft, repair of compressor crankshaft, crankshaft repair of BPCL compressor, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.