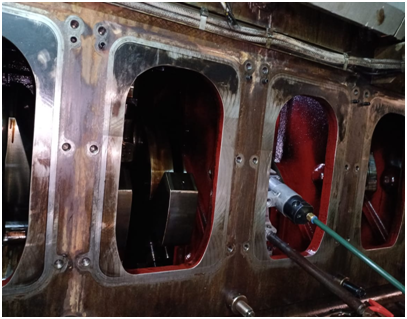

RA Power Solutions has been providing onsite inspection and machining services for new and reconditioned engine spares i.e. crankshaft, cylinder head, connecting rod, bearings, etc. for the last four decades. We are well known as the most reliable onsite crankshaft inspection and onsite crankshaft grinding service company. We deliver all the engine repair and inspection services related to high-capacity engines installed in vessel or land base power plants worldwide at short notice.

Our team of skilled and experienced technicians has repaired and inspected more than 10,000 crankshafts. RA Power Solutions specializes in onsite inspection of crankshafts, ensuring precision and reliability. Their experts employ advanced techniques to assess critical components, detect flaws, and ensure optimal performance.

The Main Highlights for the Onsite Inspection of the Crankshaft and Crankshaft Grinding Process are as follows:

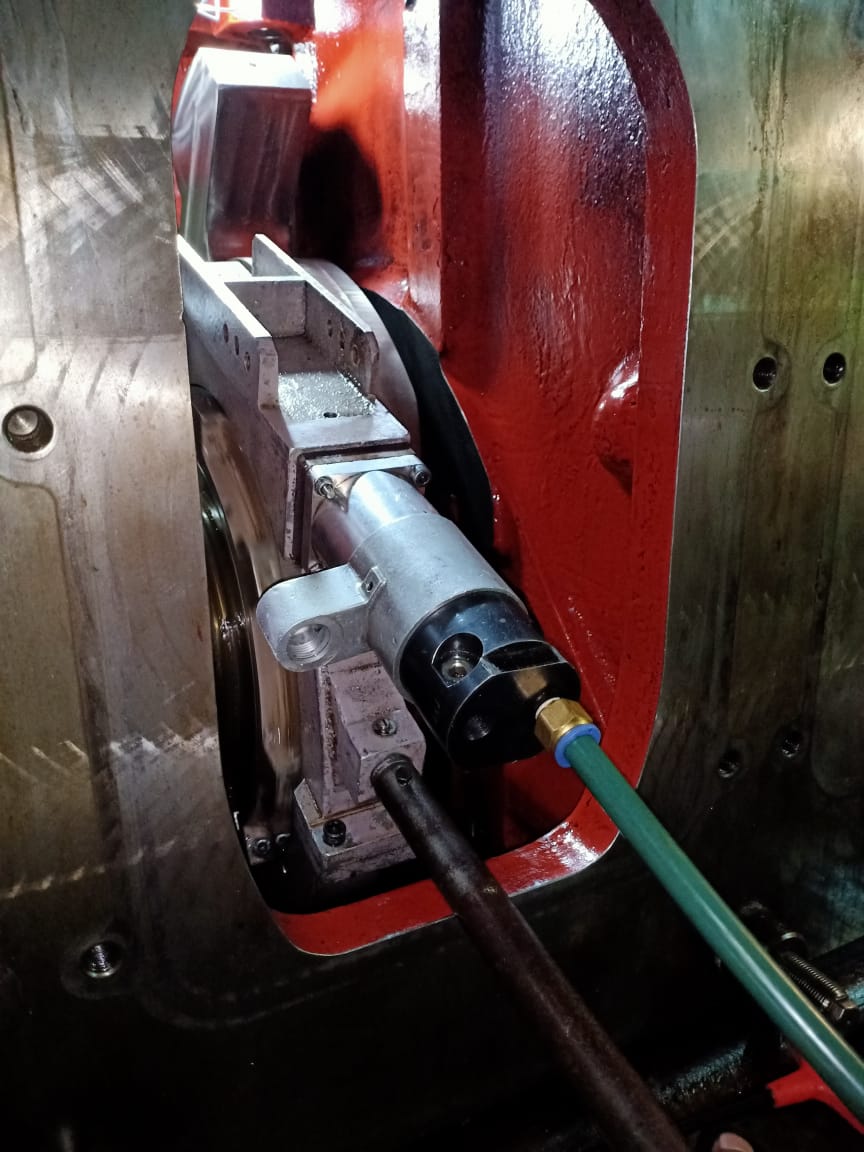

- Dimensional inspection of the crankshaft in detail is undertaken by our experienced engineers.

- Hardness check.

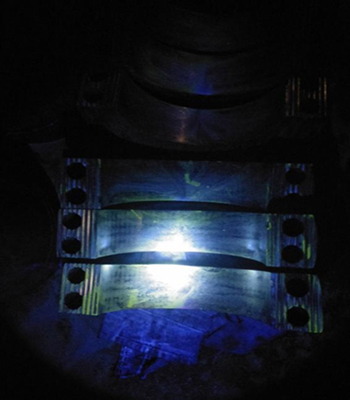

- Crack detection by MPI, dye penetrant, or ultrasonic crack detection is done.

- Visual inspection.

All the above onsite crankshaft inspections and onsite crankshaft grinding are done through the latest and verified inspection tools and equipment. After doing the insitu crankshaft inspection, our technicians prepare a detailed inspection report before repair and hand it over to the client. Based on the inspection report, a decision is made and an in situ crankshaft grinding plan is prepared. All readings reported are recorded for our clients’ quality evidence.

We also have an in-house advance facility for inspection and repair of engine spares and onsite inspection of crankshaft. We are equipped with the latest instruments and all our technicians are well-skilled for the inspection and repair of engine spares onsite or in-house.