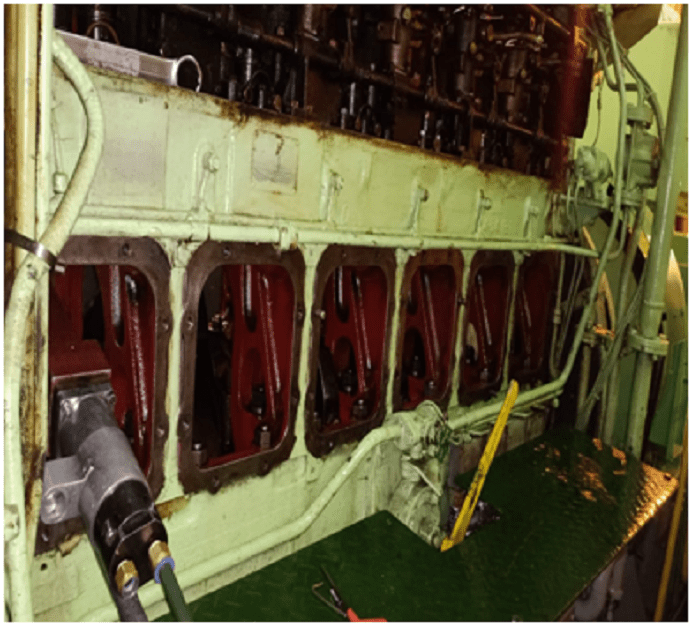

A leading shipping company based in Saudi Arabia reported a serious accident of their auxiliary engine no. 2 of Yanmar S185L-ST used as a generator. A team consisting of two technicians along with necessary calibrated instruments and an onsite crankshaft grinding machine boarded the vessel to assess the damage to the engine and to undertake crankshaft repairs.

Major Yanmar S185L-ST Engine Details are as Following

| S. NO | Crankshaft Details | |

| 1. | Engine Make | Yanmar |

| 2. | Engine Model | S185L-ST Engine |

| 3. | Crankpin Diameter Standard | 140 mm |

| 4. | Crankpin Bearing Width | 62 mm |

| 5. | Name of Vessel | MV THE ABLA |

On inspection of the crankshaft, the following were the main observations

- On the visual inspection of crankpin no. 1 having a standard diameter of 140 mm and bearing width of 62 mm, it was observed that the big end bearing failed and bearing material got embedded on the crankpin no.1 journal surface.

- The crank pin journal surface had multiple bearing line marks, was rough, and was severely scored.

- The radius fillet of both sides was damaged losing its original profile.

- Considering this to be a serious accident, all the connecting rods were disassembled and crank pins were subject to thorough inspection by our technicians.

- No deviations were observed in other crankpins on dimensional inspection.

- The hardness of crankpin no.1 was checked after removing the bearing from the crankpin journal which got embedded due to seizure of the bearing and observed within a limit.

- The crack detection test was done by a high-intensity magna flux torch and MPI equipment.

- No abnormality or cracks were observed.

- This was a big relief to our technicians as considering the serious nature of the accident, surface cracks in crank pin no. 1 were expected.

- Deflection of the crankshaft was taken and was observed within limits.

Following are the Readings Observed

The Crankpin no.1 was subject to dimensional inspection and the following readings were observed.

- Crankpin no. 1, Minimum diameter observed before repair – 139.50 mm

- Crankpin no. 1, Maximum diameter observed before repair – 139.88 mm

- Total ovality observed – 0.50 mm, considering the standard diameter of 140 mm.

Crankpin Repair Undertaken by RA Power Solutions for Successful Operation of Crankshaft of Yanmar S185L-ST Engine

- Initially, the crank pin having a standard diameter of 140 mm and bearing width of only 62 mm was ground to 0.50 mm under size with the hope the scratches and deep line marks would be removed.

- Since even after grinding 0.50 mm, the deep line marks were visible, it was decided to undersize the crank pin further by 0.5 mm.

Finally, Crankpin no. 1 was Ground to 1 mm Undersize, and Dimensions Were Maintained as Following After Grinding

- Minimum diameter observed after grinding – 138.98 mm

- Maximum diameter observed after grinding – 139.00 mm

- Maximum ovality observed – 0.02 mm

The undersized bearing of 1 mm was supplied by RA Power Solutions from their stock and the engine was put back into operation.

Main Features of Executing Successful Crankpin Repair of Yanmar S185L-ST Engine

- The company has experience of more than four decades in the field of crankshaft repair having experienced technicians trained in in-house training school.

- Manufactures its own on-site crankshaft grinding machine using it for the last 25 years. This facilitates us even to grind shafts in the limited space available.

- Only company in the world that can undertake the grinding of small diameter and main journal like in the case of Yanmar S185L-ST having a diameter of 140 mm and bearing length of only 62 mm. This needs a compact on-site crankshaft grinding machine.

- The only company in the world that can execute the grinding of crankshaft while the vessel is on the move maintaining the tolerance of 0.01/0.02 mm with a surface finish of less than 20 RA value.

- Maintaining under size and special size of bearings in stock, hence no time is wasted to put back the engine into operation.

- All technicians having Indian CDC can fly to any destination in the world on short notice.

- The on site crankshaft grinding machine is carried by our technicians as accompanied baggage and no need to book the machine in cargo and waste time in customs clearance etc.

- Light-weight machines cost less in terms of air freight charges towards transportation.

- We are considering offering our services at the lowest cost in the world.

- For a reduction in cost of the maintenance and to put back engines into operation, contact us.

We have been executing the repairs in Laos, Lebanon, Malaysia, Maldives, Mongolia, Nepal, North Korea, Oman, Philippines, Qatar, Russia, Saudi Arabia, Singapore, South Korea, Sri Lanka, Syria, United Arab Emirates, Yemen, etc. For more information about the crankshaft of Yanmar S185L-ST Engine, and Crankpin Repair, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.