RA Power Solutions has the facilities to undertake onsite grinding of crankshafts having small diameters and bearing widths. We have the onsite crankshaft grinding machine which can undertake grinding of crankshaft having bearing width as low as 40 mm. None of the companies in the world including the leading crankshaft repair companies based in Europe and other countries have the facilities and equipment to undertake grinding of crankshaft having small diameter and bearing width. RA Power Solutions was approached by a company based in Singapore to undertake the repair of the MAN B&W STX 6L 23/30H crankshaft.

The details are as follows

| S. NO | Crankshaft Details | |

| 1. | Engine Make | MAN B&W |

| 2. | Engine Model | STX 6L 23/30H |

| 3. | Crankpin Diameter Standard | 185 mm |

| 4. | Crankpin Bearing Width | 64 mm |

| 5. | Total Running Hours | 28117.5 |

| 6. | Location | West Coast Anchorage Singapore |

| 7. | Name of Vessel | MT Angelica |

Inspection of MAN B&W STX 6L 23/30H crankshaft conducted by RA Power Solutions.

- The crank pins were subject to dimensional inspection for taper and ovality.

- The ovality ranging from 0.06 to 0.11 mm was observed on all six crank pins.

- All the crank pins were subject to hardness test and hardness was observed from 219 to 231 on the HB scale which is within the limits.

- All the crankpins were subject to crack detection by high intensity magna flux torch, no cracks or abnormalities were observed.

- The deflection of crankpins was observed within limits.

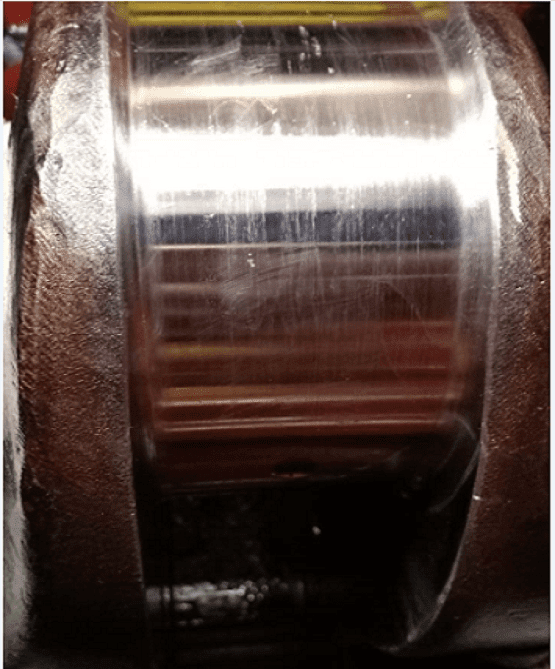

- On visual inspection, bearing line marks and a rough surface of the crankpin were observed.

Observations made by RA Power Solutions for repair of crankshaft for MAN B&W STX 6L 23/30H

The following action was taken for repair of the crankshaft of MAN B&W STX 6L 23/30H

- All the crankpins were undersized to the first step size of 0.50 mm, and the final diameter of the crankpins was maintained at 184.50 mm after grinding and polishing.

- The crank pins were polished and surface finish was maintained as per the international standards.

Save your crankshaft from rejection, contact RA Power Solutions for the right advice.

With the experience of more than four decades in the field of repair of crankshafts, we have realized that the crankshaft repair companies do not have the facilities to undertake the grinding of crank pins and main journals having small diameters and bearing widths. Their equipment is not designed to sit on the crank pin diameter due to the small bearing width.

Most of the time, these companies either reject the crankshaft for one or another reason otherwise give suggestions to send it to the workshop for repairs. With the advanced technological equipment, experience, and process RA Power Solutions has been successful in undertaking the grinding of crank pins and main journals having small diameters and bearing widths.

The above job was executed in July 2017 and is performing satisfactorily.

We have the pre and final crankshaft inspection reports undertaken on board the vessel duly signed and stamped by the chief engineer. These reports can be shared with clients on request. Take the direct benefit of our expertise and technology. For more information about the Repair of MAN B&W, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.