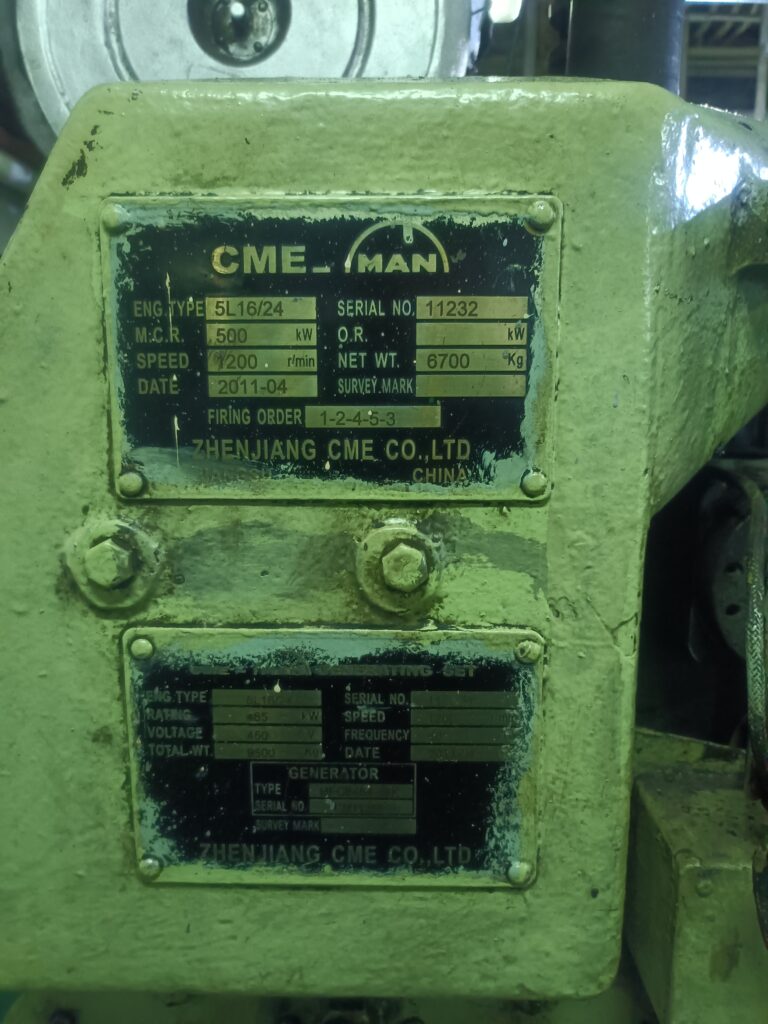

RA Power Solutions is the only company in the world that can undertake onsite grinding of crankshafts up to 700 mm in diameter even while the vessel is sailing. We successfully repaired one crankpin of a MAN B&W 5L 16/24 engine while the vessel was sailing from Fujairah Anchor (Dubai) to Galle Port, Sri Lanka.

Due to the ship owner’s commitment, they were unable to hold the vessel at the Fujairah Anchor (Dubai) and wanted the repair of damaged crankpin number four of the MAN B&W 5L 16/24 to be executed while sailing the vessel.

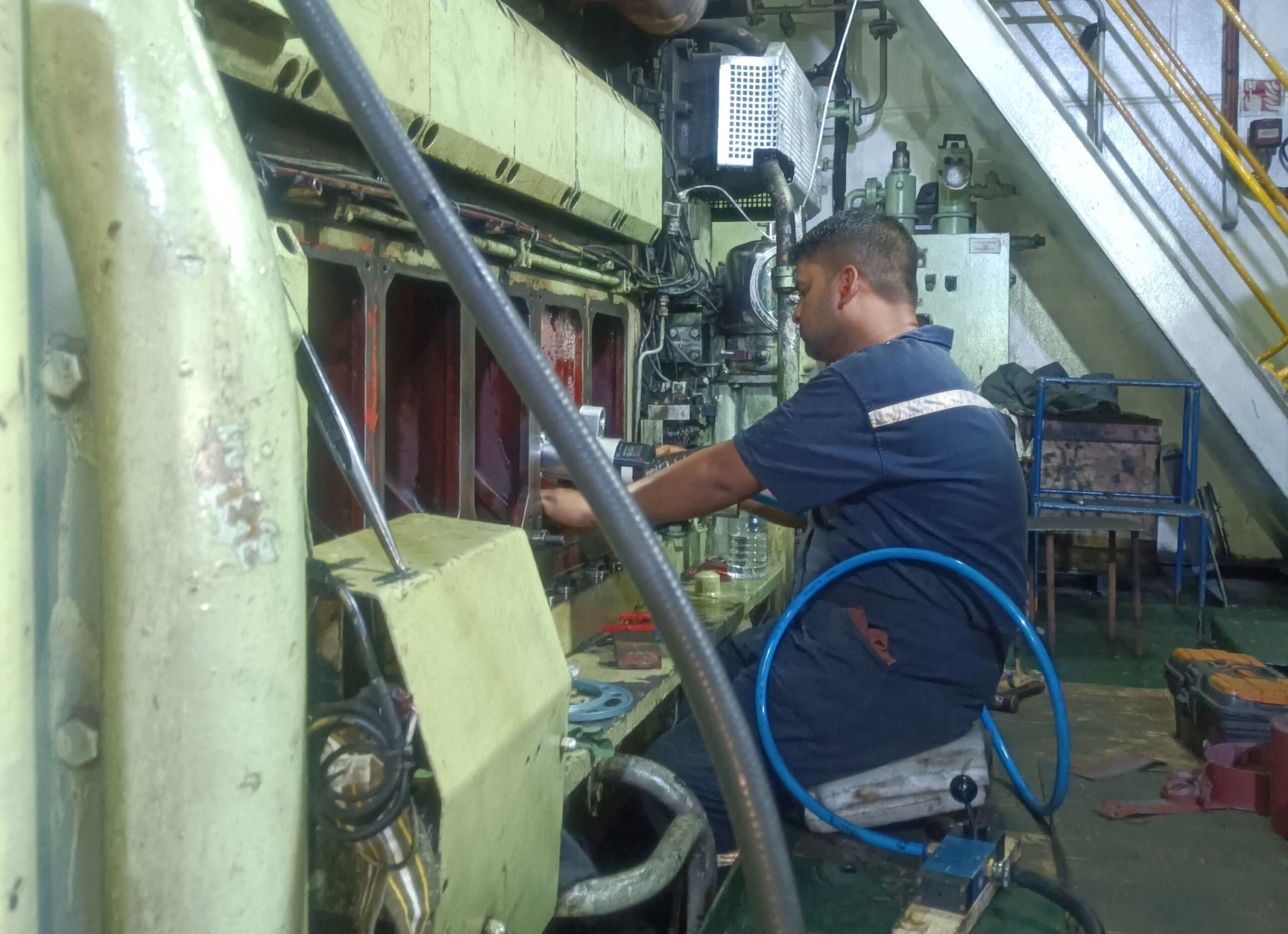

RA Power Solutions deployed two technicians to Fujairah Anchor (Dubai) with a specially designed and compact onsite crankshaft grinding machine. In the case of the MAN B&W 5L 16/24, the standard crankpin diameter is 130 mm, and the bearing length is only 56 mm, which is considered to be very small. RA Power Solutions has designed, developed, and manufactured dedicated crankshaft grinding equipment capable of grinding crankpins without removing the crankshaft from the block.

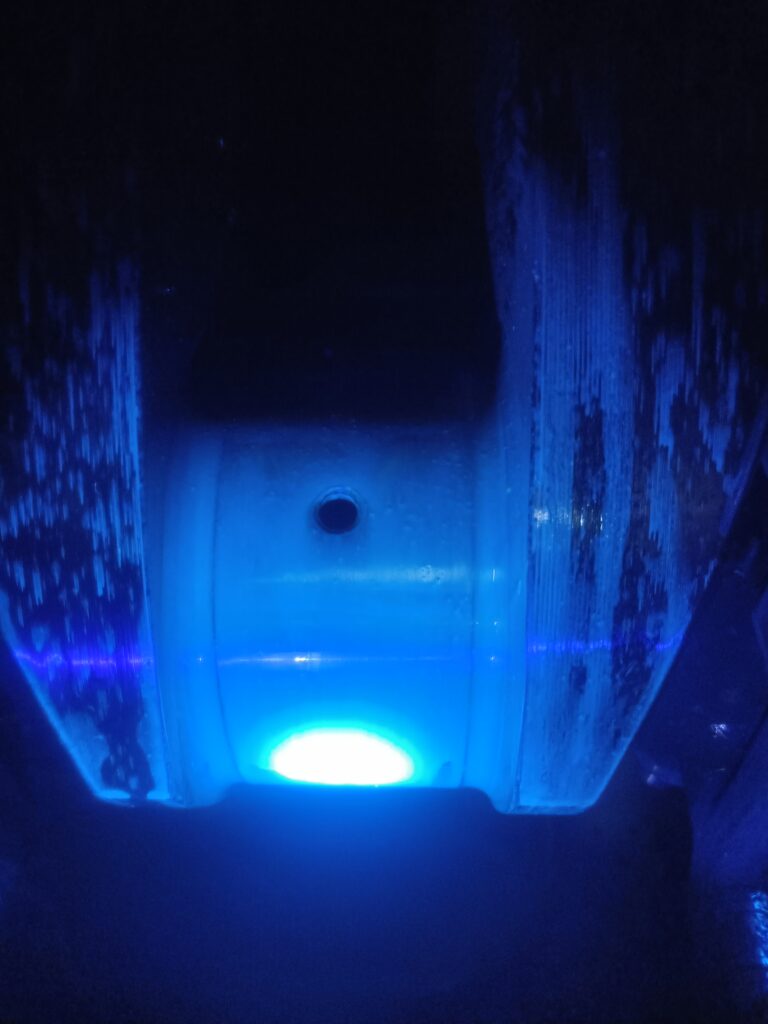

Inspection of damaged crank pin number four was conducted, and it was observed that the minimum diameter of damaged crankpin number four was as follows.

- The minimum diameter of crankpin number four is observed as 129.39 mm.

- The maximum diameter was observed at 130.00 mm.

| S. No. | Crankpin Details | |

| 1. | Engine Make | MAN B&W |

| 2. | Engine Model | 5L 16/24 |

| 3. | Crankpin Diameter Standard | 130.00 MM |

| 4. | Crankpin Bearing Width | 56.00 MM |

| 5. | Place of execution of grinding of crankpins | Fujairah Anchor (Dubai) to Galle Port Sri Lanka |

Thus, an ovality of 0.61 mm was observed, which is considered to be on the higher side. RA Power Solutions technicians executed the grinding of crankpin number four of MAN B&W 5L 16/24 while sailing from Fujairah Anchor (Dubai) to Galle Port, Sri Lanka. The crankpin number four was undersized by 1 mm, and the final diameter was maintained at 129.00 mm.

Huge Savings of Ship Owners Due to Execution Of Crankshaft Repair Which Sailing of the Ship

The repair of the crankshaft of the MAN B&W 5L 16/24 executed by RA Power Solutions resulted in huge savings for ship owners. We have the equipment, technology, and processes to execute crankshaft repairs while the vessel is sailing, with absolutely no requirement to hold the vessel for crankshaft repair.

The author is Mr. Raj Shahani, Managing Director of the company. He has 44 years of experience in grinding crankshafts, polishing crankshafts, and all services related to engine and supporting equipment repair. He has designed and developed a portable crankshaft grinding machine to save time and money.

We have been regularly providing our services in Canada, Australia, Bangladesh, Canada, Dubai, Greece, Haiti, Hong Kong, Indonesia, Kenya, Malaysia, Maldives, Kenya, Kuwait, Madagascar, Mexico, Nigeria, Oman, Philippines, Saint Lucia, Saudi Arabia, Singapore, Spain, Sint Maarten, Sri Lanka, Suriname, Thailand, Togo, United Kingdom, United States, Yemen, Zambia, etc.

For more details, crankshaft repair on vessel, onsite crankshaft grinding machine, grinding of crankshaft main journal, main journal crankshaft grinding service, crankshaft journal polishing and grinding, main journal polishing and in situ crankshaft grinding please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.