RA Power Solutions technicians recently boarded the vessel at Trincomalee port Shri Lanka crankshaft which was reportedly damaged due to bearing failure.

The major technical details of the MAN B&W 5L 16/24 engine and crankshaft are as follows:

| S. No. | Crankshaft Details | |

| 1. | Engine Make | MAN B&W |

| 2. | Engine Model | 5L 16/24 |

| 3. | Crankpin Diameter Standard | 130 MM |

| 4. | Crankpin Bearing Width | 58.50 MM |

| 5. | Place of execution of crankshaft repair | At Trincomalee Port Sri Lanka |

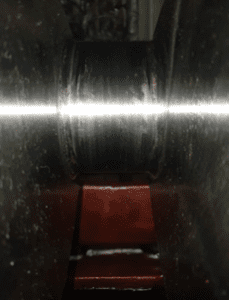

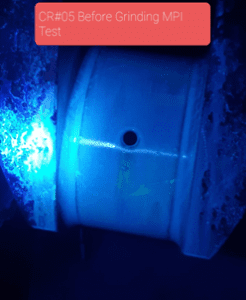

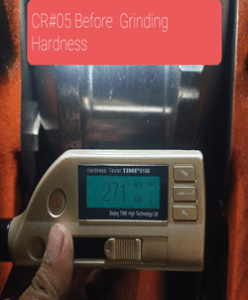

On inspection of the crankshaft it was observed that one number crankpin developed excessive ovality of 0.59 mm and bearing line marks were observed. All other crankpin dimensions were checked and found within limits.

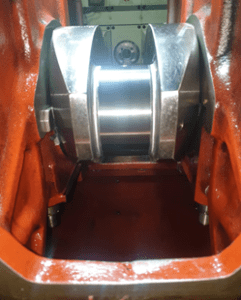

The one-number crankpin grinding was undertaken by RA Power Solutions technicians with a patented portable on site crankshaft grinding and polishing equipment carried by them & crankpin was undersize by 1.0 mm, maintaining the final dimensions of crankpin of MAN B&W 5L 16/24 as 129.00 mm and have saved the crankshaft of MAN B&W from rejection.

Our client, a leading shipping company based in Hong Kong, invited two companies to repair the crankshaft of MAN B&W 5L 16/24 from Singapore. The companies could not undertake the repairs as the grinding of the crankpin having a small crankpin width of only 58.50 mm required compact and special tooling which can be accommodated in a small crankpin width dimension. The removal of the crankshaft and sending it to the workshop was suggested to the client, which was not possible.

RA Power Solutions by undertaking the onsite grinding of crankpin saved the crankshaft from rejection and the vessel sailed within 9 hours of boarding a vessel by our technicians in Trincomalee port, Sri Lanka.

Availability of Undersize Bearings with RA Power Solutions:

RA Power Solutions deputed the technicians with 0.5 mm and 1.0 mm undersize bearings and after grinding 1.0 mm bearing was assembled and the engine was put back in operation.

A great saving by the ship owner with a cost-effective solution given by RA Power Solutions.

RA Power Solutions is ISO 9001:2015 (Quality Management System) & ISO 14001:2015 (Environmental Management System) certified approved company.

We have been regularly executing on site crankshaft repairs and crankshaft grinding in Dubai, Oman, Saudi Arabia, Qatar, Abu Dhabi, Sharjah, Ajman, Umm Al-Quwain, and Fujairah, Bahrain, Kuwait, Iraq, Antigua and Barbuda, Belize, Dominica, Dominican Republic, Grenada, Guyana, Haiti, Jamaica, Saint Kitts and Nevis, Saint Lucia, Saint Vincent and the Grenadines, Trinidad, and Tobago, etc.

For more details on the repair of the engine, crankshaft repair on the vessel, crankshaft polishing on vessel, or onboard crankshaft repair, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.