RA Power Solutions was approached by a vessel owner regarding a problem faced by them in the MAN 6L 16/24 crankshaft auxiliary engine.

The Engine Details are as Follows

| S. NO | Crankshaft Details | |

| 1. | Engine Make | AUX Engine MAN |

| 2. | Engine Model | 6L 16/24 |

| 3. | Crankpin Diameter Standard | 130 mm |

| 4. | Crankpin Bearing Width | 56 mm |

| 5. | Name of Vessel | MV. ZHONG |

Our team of two technicians boarded the vessel in Kandla, an Indian port, and inspected the crankshaft.

Following are the main observations of the MAN 6L 16/24 Auxiliary Engine Crankshaft

- The crank pin nos. two having a standard diameter of 130 mm was damaged and the minimum diameter observed was 129.79 mm.

- From the above reading, the ovality observed was 0.21 mm which is considered to be on the higher side.

- Few line marks were observed on the crank pin diameter.

- The hardness of the crankpin was checked and was observed between 243 to 276 on the HB scale which is well within the limits.

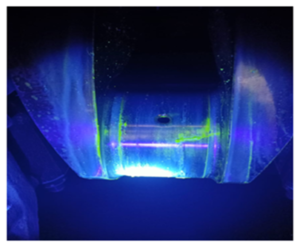

- The crankpin was also subject to a crack detection test by magnetic particle examination and no cracks were observed.

- The deflection of the crankshaft was taken and was observed within limits.

Action Taken by RA Power Solutions to Repair Crankshaft of MAN 6L 16/24 Auxiliary Engine

- Considering the ovality of 0.21 mm on the crankpin and the deep line/ dent marks observed, the crankpin was undersized to 1.0 mm.

- The minimum and maximum diameters observed after grinding were as follows:-

- Minimum diameter observed – 128.99 mm

- Maximum diameter observed – 129.00 mm

- Ovality maximum – 0.01 mm

Final reports were prepared by our technicians and the engine was put back into operation. The pre and final inspection reports duly signed by the chief engineer can be shared on request.

Achievement RA Power Solutions in Successful Repair of the Crankshaft of MAN 6L 16/24 Auxiliary Engine

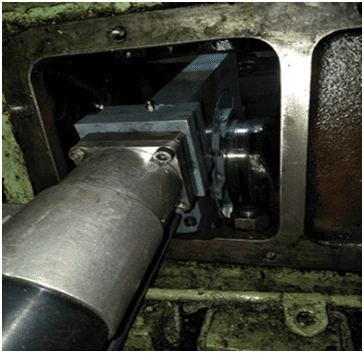

The most important aspect of the repair of the MAN 6L 16/24 auxiliary engine is that it has a small diameter of 130 mm and a bearing width of only 56 mm.

The crankshaft companies based in Europe and other countries do not have crankshaft grinding equipment which can sit on the crankpin having a bearing width as low as 56 mm. Hence, they reject the crankshaft on one excuse or another or suggest removing the crankshaft from the engine and sending it to the workshop for repairs.

RA Power Solutions is the only company that has the equipment available to work on the crankpin bearing width or main journal bearing width which is as low as 40 mm.

This technologically advanced latest generation of crankshaft grinding equipment is only available with us and have successfully repaired thousands of crankshaft all over the world in countries like Greece, Moldova, Belarus Australia, Austria, Belgium, Brazil, Cambodia, Colombia, Denmark, Ethiopia, Ghana, Haiti, etc.

For more information regarding MAN engine crankshaft repair, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.