RA Power Solutions is a leader in repairing compressor crankshafts onsite which can be seriously damaged due to an accident. The installation of a compressor may be on an oil rig on high seas, vessels oil and gas refineries, or any industry.

With the introduction of the latest design of onsite compressor crankshaft grinding machines up to 700 mm, we can undertake the repair of compressor crankshafts that get seriously damaged due to the failure of bearings, accidents, or any other reasons. The job of compressor crankshaft repair which other companies from Europe cannot undertake, we execute it successfully only because of our experience of over four decades in this field. This makes us leaders in this field.

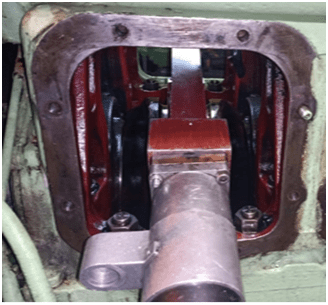

Repair of seriously damaged compressor crankshaft was successfully repaired by RA Power Solutions technicians

We were approached by a company having various oil rigs in Saudi Arabia for repair of their compressor crankshaft of reputed make of compressor having a standard crank pin diameter of 290 mm and main journal diameter of 320 mm.

Our team of senior technicians boarded the oil rig and the following action was taken for successful repair of the compressor crankshaft which was otherwise rejected by the compressor manufacturer and compressor crankshaft repair company.

- Due to the breakdown of the compressor, 60% of the operation comes to a standstill incurring heavy losses on per per-day basis.

- The crank pin of the compressor crankshaft having a 290 mm diameter was badly damaged due to the failure of the bearing. The bearing material was badly stuck on the crank pin.

- The damaged crank pin bearing was removed from the crank pin with great difficulty and the crank pin diameter was polished to undertake the inspection.

- The multiple cracks on the crank pin diameter were observed, there was higher hardness than specified, and taper and ovality of around 0.90 mm were also observed due to the failure of the bearing.

- In fact, due to the presence of multiple cracks lengths ranging from 12 mm to 119 mm, the reputed world-renowned compressor manufacturer rejected the crankshaft and advised to replace it with a new one offering delivery of 8 months from the date of placement of the order and on exorbitant price.

- After the planning of the repair strategy, the grinding of the crank pin was started.

- The number and intensity of cracks started vanishing during the process of grinding. The last under size crank pin permissible by the compressor manufacturer was 4 mm but RA Power Solutions technicians based on their experience and expertise decided to reduce the diameter of the crank pin by 6 mm and it was maintained as 284 mm against the standard crank pin diameter of 290 mm to save the compressor crankshaft from rejection and to resume the production.

- Despite undersizing the diameter by 6mm, 3 cracks measuring 10-25 mm were still present on the crank pin. The cracks on the crank pin are not acceptable as per the class and international standards.

- It was decided to remove the crack in the scooping technology.

- The cracks were fully removed by the Scooping Process and sharp edges were polished.

- The white metal Babbitt bearing was sent to our works for Rebabbitting and was sent back to the site after repairs.

- The compressor was assembled and for the last 18 months, it has been running continuously and giving satisfactory performance.

For inspection of compressor crankshaft repair and on-site repair of compressor crankshaft, please feel free to write to us or contact us for repairs with a guarantee.

Save your Compressor Crankshaft Repair from rejection, and contact RA Power Solutions.

About the author of Compressor Crankshaft Repair

This blog is written by Mr. Raj Shahani (Managing Director of RA Power Solutions India Pvt. Ltd.).

Mr. Shahani is a highly experienced business leader with rich experience of more than 40 years in the field of Power, Heavy and Shipping industry. He is a Technical Adviser to many shipping and heavy industries across the globe.

Mr. Shahani is one of the most enthusiastic professionals and he has all the brilliance of an exemplary leader. Mr. Shahani is an extremely effective coach and mentor of teams and is adept at providing leadership in a global, cross-cultural environment.

For more information, Compressor Crankshaft Repair, in situ crankshaft grinding, and crankpin repair services please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.