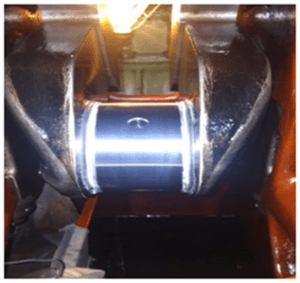

RA Power Solutions was advised about the failure of the two auxiliary engines crankshaft of Daihatsu 5DC-17 in the Suez Canal because of which the vessel was not able to sail. The owners of the vessel made a distress call for repair of the crankshaft. They checked from few European-based companies for grinding of the crankshaft but they couldn’t do the repairs because of the non-availability of equipment. The standard crank pin diameter is only 145 mm and the bearing width of 64 mm this needs very compact equipment to be placed on the damaged crank pin diameter to undertake grinding and polishing.

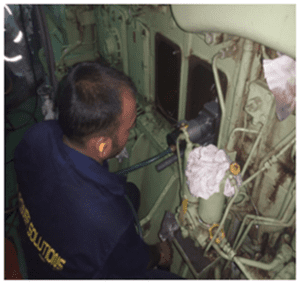

Two technicians with portable onsite crankshaft grinding machines were deputed to Cairo Egypt and boarded the vessel within 15 hrs of the first intimation call. This was possible as all our technicians have valid seamen books.

Daihatsu Auxiliary Engine 5DC-17 Inspection by RA Power

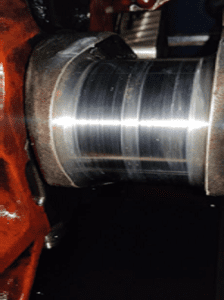

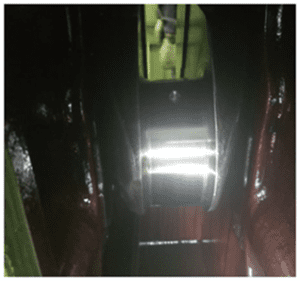

On undertaking the inspection excessive ovality ranging from 0.20 mm to 0.50 mm was observed in the case of both the crankshaft all other parameters like hardness, MPI, etc were observed within limits.

The grinding of AE#01 and AE# 03 crankshaft was undertaken by 1.0 mm undersize against the standard size of 145 mm. The diameter was reduced to 144 mm.

|

|

|

RA Power Solutions also supplied the undersized crank pin bearing of 1.0 mm from ready stock.

RA Power Solutions has undertaken onsite crankshaft grinding up to 700 mm diameter and extending services all over the world for the last 43 years.

|

|

|

For more details on the crank pin grinding repair, Daihatsu 5DC-17 crankshaft repair, and Daihatsu auxiliary engine 5DC-17, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.