RA Power Solutions was approached by a leading shipping company based in Dubai regarding a problem faced by them due to damage to two crankpins of the Daihatsu auxiliary engine on board a vessel and onsite crankshaft replacement.

The details of the crankshaft of Daihatsu 6DL-16 are as follows:

| S. No. | Crankshaft Details | |

| 1. | Engine Make | Daihatsu |

| 2. | Engine Model | 6DL-16 |

| 3. | Crankpin Diameter Standard | 120 mm |

| 4. | Crankpin Bearing Width | 65 mm |

| 5. | Place of execution of crankshaft repair | At Khalid Port Sharjah UAE |

Inspection Conducted by RA Power Solutions technicians and observations:

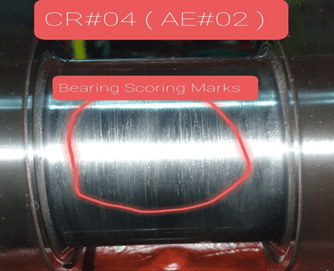

- On arrival, the inspection in detail was conducted by our technicians.

- It was informed that a local company based in Dubai was engaged to undertake the repair of two crankpins that were damaged.

- The crankshaft repair company based in Dubai took eight days to repair the two crankpins and the bearings failed twice within engine operation of 10 minutes.

- RA Power Solutions technicians did the dimensional inspection of crankpins. They were surprised to note that the crankpins after grinding by a Dubai-based company had ovality up to 0.12 mm against the maximum permissible limit of 0.03 mm by Daihatsu.

- The readings observed by our technicians before grinding are mentioned below:

SIZE OF CR JOURNAL SIZES IN MM

| A | Aa | C | Cc | B | Bb | Min | MM U/S | Ovality | |

| CR-1 | 119.38 | 119.38 | 119.39 | 119.38 | 119.39 | 119.40 | 119.38 | 119.50 | 0.12mm |

| CR-2 | |||||||||

| CR-3 | |||||||||

| CR-4 | 119.45 | 119.40 | 119.46 | 119.38 | 119.45 | 119.41 | 119.38 | 119.50 | 0.12mm |

- On further investigation, RA Power Solutions was informed that the company from Dubai had no specialized equipment/ tooling to undertake the grinding of Daihatsu 6DL-16 having a standard diameter of 120 mm and crankpin bearing width of only 64 mm. They did it by hand and were not able to control the ovality.

Action taken by RA Power Solutions Technicians

RA Power Solutions technicians after initial inspection for dimensions, hardness, MPI for crack detection, etc undertook the grinding of crankpins 1 & 4 and undersized both the crankpins by 1.0 mm.

The Final report after grinding is pasted below:

SIZE OF CR JOURNAL SIZES IN MM

| A | Aa | C | Cc | B | Bb | Min | Max | Ovality | |

| CR-1 | 118.99 | 118.98 | 118.99 | 119.00 | 118.99 | 118.98 | 118.98 | 119.00 | 0.02mm |

| CR-2 | |||||||||

| CR-3 | |||||||||

| CR-4 | 118.98 | 118.99 | 119.00 | 119.00 | 118.99 | 118.98 | 118.98 | 119.00 | 0.02 mm |

It can be seen from the above readings that the taper & ovality were controlled within 0.02 mm. The engine was commissioned in the presence of our technicians and was operating satisfactorily.

Achievement by RA Power Solutions

The grinding of the crankpin of Daihatsu 6DL-16 needs specially designed, compact onsite crankshaft grinding equipment which RA Power Solutions has developed. This equipment is manufactured in two parts and is inserted from the inspection window of the engine block.

In this case, the crankpin diameter is only 120 mm, and the crankpin bearing width of 64 mm, we have designed the equipment that can undertake grinding/ polishing of the crankpin without removing it from the entablature.

We have been extending our onsite services all over the world for the last forty-three years and regularly work on high RPM engines like Daihatsu, Yanmar, Volvo, MAN B&W, Caterpillar, Cummins, Deutz Engines, etc.

RA Power Solutions is ISO 9001:2015 (Quality Management System) & ISO 14001:2015 (Environmental Management System) certified approved company.

We have been regularly executing the on-site crankshaft repairs and crankshaft grinding in Dubai, Oman, Saudi Arabia, Qatar, Abu Dhabi, Sharjah, Ajman, Umm Al-Quwain, and Fujairah, Bahrain, Kuwait, Iraq, Antigua and Barbuda, Belize, Dominica, Dominican Republic, Grenada, Guyana, Haiti, Jamaica, Saint Kitts and Nevis, Saint Lucia, Saint Vincent and the Grenadines, Trinidad, and Tobago, etc.

For more details on the Repair of the engine and onsite crankshaft replacement, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.