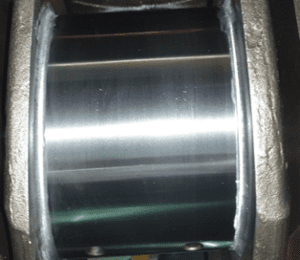

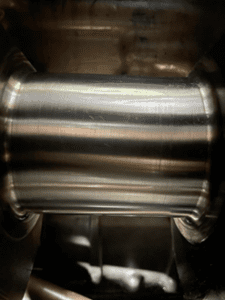

Cummins and Caterpillar engines are generally high RPM engines that are compact in design. In case of seizure of bearing, development of bearing line marks, rough surface, or development of ovality due to continuous operation the Cummins and Caterpillar engine owners have no option but to remove the crankshaft from the engine block and send it to the designated workshop for grinding & polishing purpose.

In fact, in several cities/islands/ countries they have no facility for polishing/ grinding of crankshaft and clients have no option but to send the crankshaft for repair to a third country.

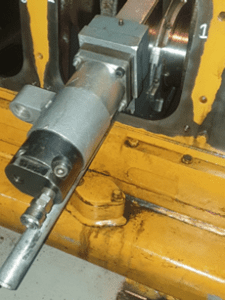

RA Power Solutions has forty-three years of experience in onsite grinding/ polishing of crankshafts up to 700 mm diameter. After continuous research, we have developed a compact and portable crankshaft grinding machine which can undertake the grinding and polishing of Cummins and caterpillar engine crankshaft without removing it from the engine block

The main features are as follows:

Grinding/ Polishing of Cummins and Caterpillar Crankshaft on-site

- The onsite grinding equipment developed by RA Power Solutions is portable, compact, and lightweight. It can be carried to any installation all over the world as accompanied baggage hence no time is wasted in transportation.

- The equipment is manufactured in two parts and is inserted from the inspection window. It sits on the crank pin diameter and undertakes grinding and polishing.

- The tolerance is maintained as per the manufacturer’s requirement.

- After polishing the surface finish is improved and can be maintained at less than 15 RA value which is far better than the international standard.

- We have a team of trained technicians available 24/7 hrs and can be deputed on short notice. Some of our technicians also have valid US VISA and can fly to South America, Caribbean countries, etc.

We have been regularly executing on site crankshaft repairs and crankshaft grinding in Dubai, Oman, Saudi Arabia, Qatar, Abu Dhabi, Sharjah, Ajman, Umm Al-Quwain, and Fujairah, Bahrain, Kuwait, Iraq, Antigua and Barbuda, Belize, Dominica, Dominican Republic, Grenada, Guyana, Haiti, Jamaica, Saint Kitts and Nevis, Saint Lucia, Saint Vincent and the Grenadines, Trinidad, and Tobago, etc.

For more details on the crank pin grinding repair, crankshaft grinding onsite, and Cummins Crankshaft Grinding, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.