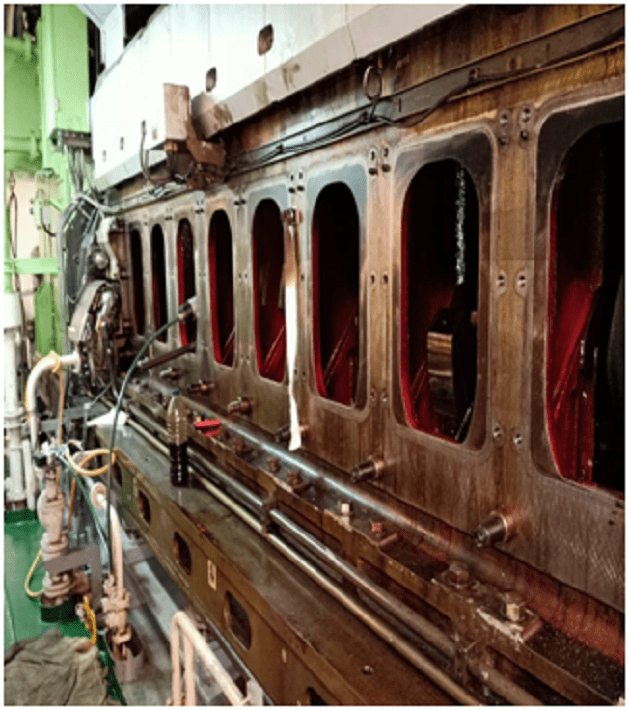

RA Power Solutions undertakes crankshaft repair of diesel engines used as generators, marine engines & auxiliary engines, compressors, forging hammers, and all heavy rotatory equipment having crankshaft or cylindrical shafts up to 700 mm in diameter.

We have been extending onsite crankshaft repair services for medium & heavy equipment for over four decades and the services are extended all over the world. We also execute repairs of the crankshaft on a moving vessel and there is no requirement to hold it.

Advantages of Crankshaft Repair Services offered by RA Power Solutions

We are mentioning below a few of the advantages of getting crankshaft repair executed by RA Power Solutions.

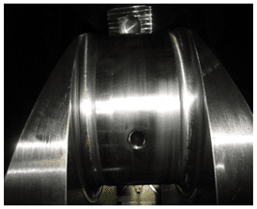

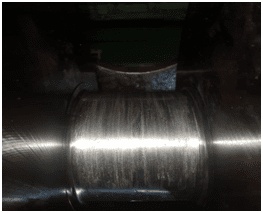

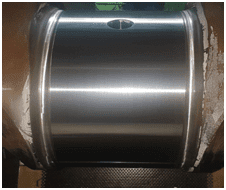

- We believe that the crankshaft is a piece of art and even for the heavy crankshafts the tolerance in terms of taper and ovality ranges between 20 to 50 microns which is very little and requires experience, special skill, and dedicated latest design of equipment to maintain.

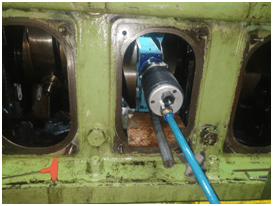

- A Power Solutions is the only manufacturer of the onsite crankshaft grinding machine in the world and has supplied over 70 machines which are in operation by leading shipping companies, Power Plants repair workshops, etc.

- Our designing and manufacturing of onsite crankshaft grinding machines for crankshaft repair can be easily modified according to the site requirements.

- Difficult and serious damage to the crankshaft is successfully repaired as we have in-house capability of modifying our equipment as per the site requirement and condition.

- Most of the companies based in Europe, and the UK undertaking crankshaft repair cannot successfully execute the repair of crankshaft radius fillet which is damaged or worn out due to accident. They always recommended either removing the crankshaft from the engine block and sending it to the workshop or rejecting it.

- We have onsite crankshaft grinding equipment by which repair of the crankshaft can be successfully executed despite damage to the radius fillet of both sides. We have a record of more than thousands of crankshaft repair cases where the radius fillet was damaged.

- We have facilities and modern equipment to undertake non-destructive tests including hardness checks, crack detection checks by MPI dimensions checks, etc.

|

|

|

Availability of trained & experienced technicians for crankshaft repair

- All our technicians are trained in our in-house training school near New Delhi, the capital of India.

- The technicians are trained on dummy crankshafts under senior supervision and have experience of 30 and 40 years in crankshaft repair.

- Our mission is to create awareness and make it understandable to our clients all over the world that it is not a difficult task to repair the crankshaft, which few companies have been propagating and making a monopoly by charging exorbitant prices.

|

|

|

Low cost of crankshaft repair offered by RA Power Solutions

- We are the cheapest in the world executing crankshaft repair at minimum cost.

- We don’t charge separately for NDT tests, cost for repair of radius fillet, out-of-station allowance, etc.

- We have successfully executed damaged crankshaft repair of MAN B&W, Yanmar, Daihatsu, Wartsila, Ruston & Hornsby Engine, etc.

|

|

|

For more information regarding crankshaft repair services, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.