The objective of RA Power Solutions is to successfully undertake the repair of the crankshaft to ensure satisfactory performance. We are experts in crankshaft reconditioning with over 44 years of practical experience in saving the crankshafts from rejection and enhancing the crankshaft life cycle.

Don’t get repairs done from inexperienced companies:

This is important as we have observed that shipping companies get in touch with the general workshops that have no experience, expertise, or dedicated equipment for crankshaft repairs. This results in substandard repairs and rejection of the crankshaft as the tolerances specified by the manufacturers are not maintained.

Secondly, we have also noticed that in certain cases to immediately put the engine into operation, the hand polishing is done by rope or any other polishing media. We have experienced that by no way the taper and ovality can be minimized or controlled by hand polishing. The hand polishing of the crankpin and journal of the crankshaft only improves the surface finish which is of no use in case taper and ovality in the crankpin/main journal diameter is present.

Making Informed Decisions About Crankshafts Repair

The managers and the marine engineers should keep in mind not only the exorbitant price of the crankshaft but also its availability and the efforts required to connect it to the vessel. At RA Power Solutions, we consider a crankshaft to be a piece of art having the closest possible tolerances and requirement of high surface finish, we have with our experience learned to investigate in-depth the problem in the crankshaft and prepare the plan for crankshaft grinding repair.

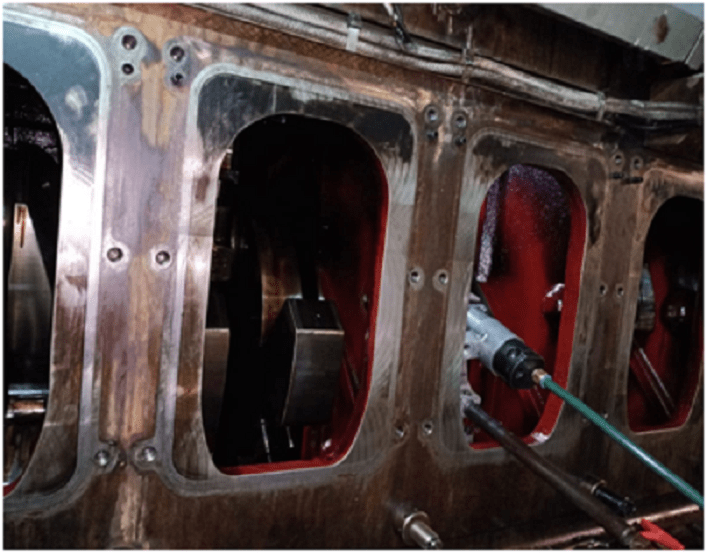

We have saved thousands of crankshafts from rejection which were spoiled because of the wrong procedure of crankshaft repair followed by inexperienced and small repair companies. The most modern onsite grinding equipment available with us is up to 700 mm in diameter. With a combination of experienced technicians and onsite crankshaft grinding equipment, we ensure that crankshaft repair is done strictly as per the manufacturer’s specifications and international standards.

In this time of recession, the cost of crankshaft reconditioning is of great importance. We are considered to be the lowest-priced company in the world giving tough competition to the crankshaft repair companies based in Europe, Singapore, and the UK, who till now enjoyed the monopoly and charged exorbitant amounts from the ship owners.

We are also the manufacturer of onsite portable grinding machines. The machines are manufactured based on our experience in this field and the inputs given by our technicians from time to time. More than 70 onsite crankshaft grinding machines have been sold all over the world. We also extend training to the clients, and technicians to ensure that they can execute the crankshaft reconditioning successfully.

Need more information on crankshaft repair and crankshaft reconditioning, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.