RA Power Solutions Pvt. Ltd. was approached by ship managers based in Dubai advising about the failure of the crankshaft of MAN B&W Diesel Engine Model CME 5L16/24. RA Power Solutions technicians in a short time boarded the vessel crankshaft repair and inspected the crankshaft of MAN B&W Diesel Engine Model CME 5L16/24.

Following are the main observations of MAN Diesel Engine

| S. NO | Crankshaft Details | |

| 1. | Engine Make | MAN B&W Diesel Engine |

| 2. | Engine Model | CME 5L16/24 |

| 3. | Crankpin Diameter Standard | 130.00 mm |

| 4. | Crankpin Bearing Width | 56 mm |

| 5. | Name of Vessel | MV LIALA |

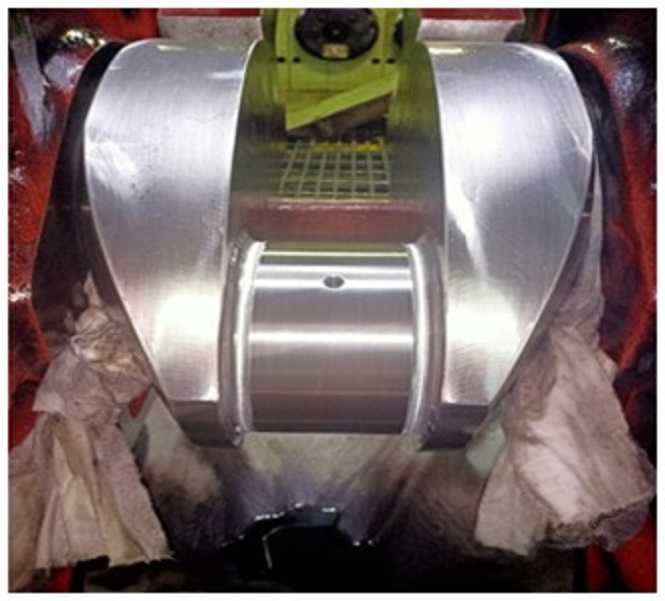

- The crank pin of the engine has a diameter of 130 mm with a bearing width of 56 mm.

- All the crank pins had scoring marks and bearing line marks due to the seizure of the crankpin bearing.

- The dimensional inspection was done and the crank pins had taper and ovality in the range of 0.2 mm to 0.4 mm.

- The hardness was checked and was observed within the limits.

- MPI check was done and few hairline cracks were observed.

- The deflection and runout were observed within the limit.

Action taken by RA Power Solutions

- The grinding of crank pins was undertaken and all the crank pins diameter was maintained within 0.4 mm.

- Crankpin No.3 had deep bearing line marks due to the seizure of the crankpin bearing. The grinding of the crank pin to 0.6 mm was done which is the last size recommended by the engine manufacturer.

- As per the manufacturers since the damage to the crankpin was more than the last limits specified Crankshaft stands rejected and the purchase of a new crankshaft was recommended.

- To save the crankshaft from rejection, RA Power Solutions decided to continue the grinding of the crank pin to the undersize of 1.0 mm under deviation

- The under-size bearing was supplied through one of our associate manufacturers of bearings. The engine was put into operation and has been performing satisfactorily for the last more than nine months.

Expertise available with RA Power Solutions to save the crankshaft from rejection

Having on hand experience of more than forty years, RA Power Solutions has repaired thousands of crankshafts of marine engines and engines installed in power plants which were rejected by the engine manufacturer for the following reasons.

- The damage to the crankpin or main journal was more than the last limit specified by the engine manufacturer.

- Presence of cracks in the crank pin and main journal.

- Observation of higher hardness due to the seizure of bearing.

- Observation of higher runout and deflection.

- RA Power Solutions as the name suggests has the well-tried and tested solution, technology, and equipment available to repair the diesel crankshaft having the above defects.

Don’t reject the crankshaft, reduce the cost of maintenance, and contact RA Power Solutions for a successful repair. Use our technology, equipment, and experienced technicians to save your crankshaft from rejection.

Diesel engine crankshaft repair by RA Power Solutions is a testament to precision and expertise in the field. Whether it’s addressing crankshaft damage due to wear and tear or unforeseen failures, RA Power Solutions is the go-to partner for comprehensive and efficient diesel engine crankshaft repair, guaranteeing minimal downtime and maximum performance.

Our technicians are qualified and possess the necessary certifications for sailing, allowing for the overhauling and repair of diesel engine services and the replacement of crankshafts and other components while the vessel is still at sea. This approach reduces the cost associated with docking or holding the vessel at port for engine repairs.

For more information, about MAN Diesel Engine, and diesel engine crankshaft repair, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.