Major accident took place in the case of Auxiliary Engine MAN B&W 6L 16/24 on board a vessel owned by a leading Malaysian shipping company. The photographs of the damaged engine block and crankshaft were shared with RA Power Solutions.

Considering the serious damage to the Auxiliary Engine MAN B&W 6L 16/24, a team of three (3) technicians was deputed, which consisted of a Senior Metal Stitching Engineer and Two (2) technicians to repair the crankshaft.

The vessel was boarded by our technicians in Pasir Gudang. Following are the main details of the engine:

| S. No. | Crankpin Details | |

| 1. | Engine Make | MAN B&W |

| 2. | Engine Model | 6L 16/24 |

| 3. | Crankpin Diameter Standard | 130.00 MM |

| 4. | Crankpin Bearing Width | 56.00 MM |

| 5. | Place of Execution of Grinding of Crankpin | Pasir Gudang Anchorage, Malaysia |

| 6. | Name of Shipping Company | Reputed Company from Kuala Lumpur |

Inspection of Crankshaft:

- All the crankpins were inspected dimensionally, and line marks and ovality were observed on all the crankpins. The standard diameter of crankpin was 130.00 MM.

- All other parameters, like hardness, and crack detection by MPI, were found within limits.

- On visual inspection of the radius fillet of two (2) crankpins was found damaged.

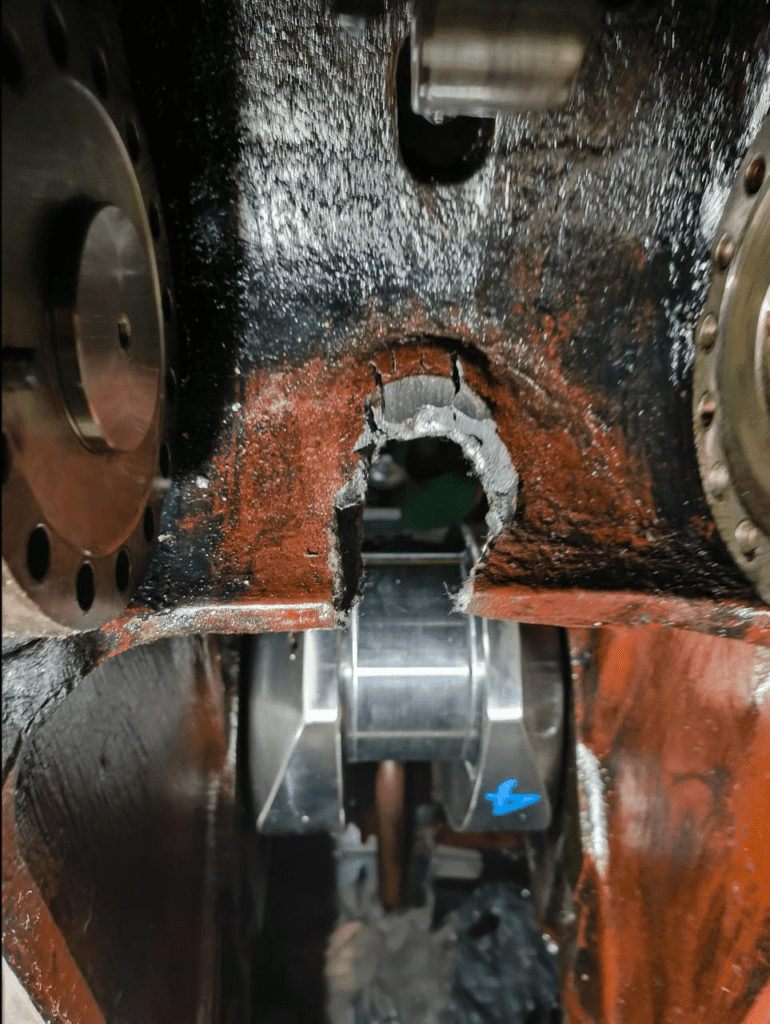

Inspection of Engine Block

- The Engine Block window seating area of Unit number #04 (Port Side) was found badly damaged.

- The Cam Case was also found broken.

Few Photographs of the damaged Cam Case are given below:

| Broken Camshaft Area of the Window | Damaged Window cover Sittting Area |

|

|

Action Taken by RA Power Solutions to Repair of Crankshaft and Engine Block of MAN B&W 6L 16/24

i. Considering the damage, all six (6) crankpins diameter was reduced from 130.00 Mm to 129.50 MM, maintaining the tolerance of 0.02 MM.

A copy of the report indicating the final dimensions is pasted below:

| SIZE OF CR PINS AFTER REPAIR | |||||||||

| A | Aa | C | Cc | B | Bb | Min | US

(0.50 MM)

|

Ovality | |

| CR-1 | 129.48 | 129.49 | 129.49 | 129.48 | 129.50 | 129.50 | 129.48 | 129.50 | 0.02MM |

| CR-2 | 129.48 | 129.49 | 129.50 | 129.49 | 129.48 | 129.49 | 129.48 | 129.50 | 0.02MM |

| CR-3 | 129.49 | 129.50 | 129.50 | 129.48 | 129.49 | 129.50 | 129.48 | 129.50 | 0.02MM |

| CR-4 | 129.48 | 129.49 | 129.48 | 129.50 | 129.48 | 129.50 | 129.48 | 129.50 | 0.02MM |

| CR-5 | 129.49 | 129.49 | 129.48 | 129.50 | 129.48 | 129.49 | 129.48 | 129.50 | 0.02MM |

| CR-6 | 129.48 | 129.49 | 129.49 | 129.50 | 129.50 | 129.48 | 129.48 | 129.50 | 0.02MM |

ii. The broken engine block was repaired by Metal Stitching Process. The new pieces of casting were metal stitched as shown in the photographs.

| Initial Cut Given in Engine Block Window Area | Fitment of New Casting in Damaged Area |

|

|

| MAN B&W Model No.6L 16/24 during metal lock | Metal locking of broken area of MAN B&W Model No.6L 16/24 |

|

|

iii) The Undersize bearings were also supplied by RA Power Solutions.

iv) The Engine was commissioned in the presence of our technicians and performance was found satisfactory.

| Pasting of Casting by Metal Lock Process | Perfect Matching of Casting After Metal Locking |

|

|

| Cam Cover Area Metal Stitched |

|

We have been regularly executing on site crankshaft repairs and In Situ Crankshaft Grinding in Dubai, Fujairah, Qatar, Saudi Arabia, Oman, Iraq, Togo, Malta, Freetown, Egypt, Malaysia, Iran, Indonesia, Vietnam, Jordan, etc.

For more details of the Damaged Engine Block by Metal Stitching Process, Onboard Crankshaft Repair Services, repair of crankshaft onsite, in situ crankshaft grinding and repair of MAN engine, onsite crankshaft grinding repair services, onsite crankshaft grinding and repair please email us at info@rapowersolutions.com or call +91 9582647131, or +91 9810012383.