It is observed that in most cases, maintenance engineers on board a vessel or in the power plant are particular about the replacement of crankpin and main journal bearings as per the schedule stipulated in the maintenance manual of the engine manufacturer. It is observed that not much attention is paid in the inspection of the crankshaft before the replacement of bearings with new ones, RA Power Solutions having experience of over four decades recommends following the inspection procedure for crankshaft before the fitment of bearings which should be followed for enhancement of the bearing life and to avoid any major breakdown of the crankshaft.

Following inspection of the crankpin and main journal is recommended before the replacement of the crankpin and main journal bearings.

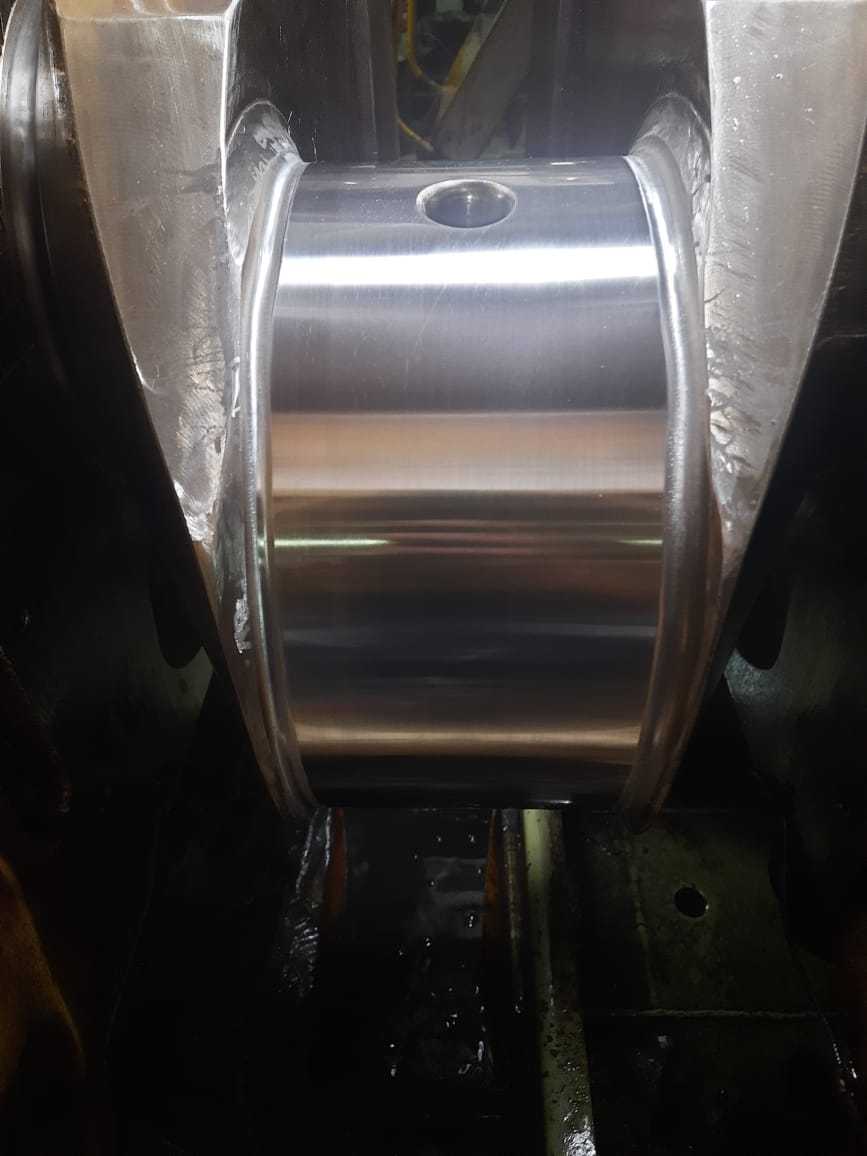

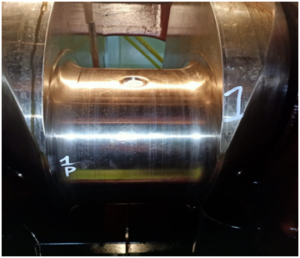

Dense, scoring, and bearing marks should be thoroughly checked. In some cases, bearing material sticking on the crankpin/main journal takes place. This needs to be checked thoroughly. Development of rough surface on crankpin and main journal diameter. RA Power Solutions Pvt Ltd. recommends crankshaft polishing to save the crankshaft from rejection.

In case any of the above-mentioned abnormalities are observed on the crankpin and main journal surface, polishing is recommended. The crankshaft journal and crankpin are required to be polished maintaining the RA value of less than 15/10 micro inch depending on the rpm of the engine and manufacturer.

The polishing of the crankpin and main journal is recommended to prevent rapid premature wear and tear of the crankshaft and to increase the life of bearings. It is strongly recommended that whenever the bearings are replaced, the crankshaft should be subject to polishing to remove the burrs, line marks and to enhance the surface finish.

In olden times, it was not possible to undertake the crankpin and main journal polishing on site due to the non-availability of technology and equipment. End users and marine engineers were reluctant to remove the crankshaft from the engine block and send it to the designated workshop which used to work out to be expensive and time-consuming. With the introduction of an onsite crankshaft polishing machine, RA Power Solutions can depute our engineers along with a crankshaft polishing machine on board a vessel or any site all over the world on short notice. The equipment is designed to maintain a far superior surface finish of 15/20 microinch which is the international standard.

Polishing Crank Journals And Main Journal Polishing Made Easy

Are you spending a huge amount still on crankpin and main journal polishing on the crankshaft and paying exorbitant rates to companies based in Europe and Singapore? RA Power Solutions Pvt. Ltd. undertakes crankpin and main journal polishing onsite up to 700 mm diameter at an internationally low price. All the parameters after crankpin and main journal polishing are maintained.

A few of the advantages of crankpin and main journal polishing are the following:

It is recommended to remove the bearing line marks and pitting from the crankpin and main journal periodically. After the continuous running of the engine, the crankpin and main journal surface become rough. This can be polished and surface finish can be maintained as per the international standards.

Crankpin and main journal polishing are recommended to remove the excessive taper and ovality in the crankpin and main journal. We can depute technicians with the portable crankpin and main journal polishing equipment and undertake the job. Alternatively, for large diesel power plants or shipping companies, it is recommended to buy the onsite crankshaft grinding machine manufactured by RA Power Solutions.

The negligible cost of crankshaft polishing

The cost of crankshaft polishing is negligible in comparison to the consequences due to the major breakdown of the crankshaft. The cost of replacing a new crankshaft and bearings is exorbitant. RA Power Solutions Pvt. Ltd. recommends availing the facilities of getting the inspection of the crankshaft and polishing done.

For more information on crankshaft grinding, crankshaft inspection procedure, crankshaft repair, crankshaft journals polishing, polishing crankshaft journals, crankshaft inspection procedure, grinding of crankshaft journal, crankpin grinding, polishing crank journals, crankshaft inspection procedure, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.