RA Power Solutions is ISO 9001:2015 (Quality Management System) & ISO 14001:2015 (Environmental Management System) certified approved company extending crankshaft inspection & crankshaft repair services all over the world for the last 41 years.

We have trained, qualified, and experienced technicians to undertake crankshaft inspection & to execute the crankshaft repair successfully after Pre-inspection is conducted.

Following services for crankshaft inspection on site & crankshaft repair are offered

- Inspection services for damaged crankshaft onsite or on board a vessel.

- In case of damaged crankshaft, we depute our experienced technicians to undertake inspections all over the world for land-based Diesel engines or main & auxiliary engines installed on the vessel.

- Technicians travel to the site in the minimum possible time as all our technicians have the necessary certificates & CDC which facilitates them to fly to any destination all over the world.

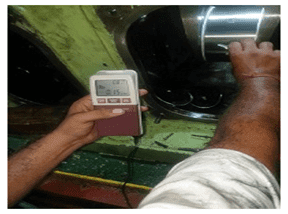

- Technicians carry with them calibrated latest breed of instruments to conduct the crankshaft inspection and crankshaft repair on site.

The crankshaft inspection includes the following

- Visual inspection of radius fillet, lubricating oil hole, counterweight, and complete crankshaft for any damage.

- Dimensional inspection of crankpin and main journal (in case possible) to check taper & ovality.

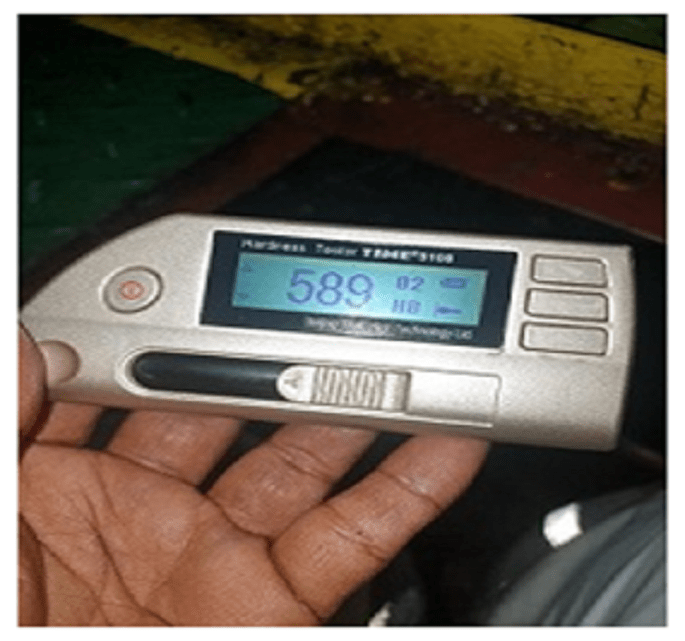

- Hardness test.

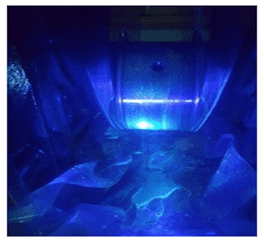

- Crack detection by MPI with the latest model of high-intensity magnaflux torch.

- In certain cases, a dye penetrant test is also undertaken.

- Surface roughness test by the latest model of the Mitutoyo surface testing instrument.

- Computerized reports are prepared in RA Power technical format and are submitted to the client.

- In case required RA Power Solutions can immediately depute a team of technicians with an onsite crankshaft/ cylindrical shaft grinding machine to execute the repair as per the International standards & specifications.

|

|

|

Inspection of the Crankshaft of the MAN Engine for purchase/ Replacement

The shipbreaking yard of Alang based in western India is coming up as the largest shipbreaking yard in the world. We offer crankshaft inspection services in case any of our clients want to purchase a used crankshaft or any major components like the engine block, connecting rod, cylinder head, turbocharger, etc. We also have the facility to undertake in-house reconditioning of the major parts removed from the engine.

Inspection of the crankshaft of the MAN Engine during routine maintenance

We strongly recommend inspection of the crankshaft during the routine maintenance of marine engines, and engines in operation in industries. The cost of on site inspection is negligible in comparison to the cost of a new crankshaft which needs replacement in case of damage. During the maintenance period, our technicians visit the installation and inspect the crankshaft in detail. We have the latest design of portable polishing & grinding machines available up to 700 mm diameter so that timely necessary corrective action can be undertaken.

We also conduct on site inspections of the following parts

- Turbine shaft

- Alternator shaft

- Rotor shaft

- Pump shaft

- Gear Box shaft

We have been regularly executing the inspection and repairs in Madagascar, Oman, Qatar, Philippines, Bahrain, Srilanka, Bangladesh, Myanmar, Turkey, Nigeria, Greece, Saudi Arabia, UK, Dubai, Malta, Cyprus, Singapore, Malaysia, Colombia, Indonesia, Hong Kong, Spain, Netherlands, Dubai, Portugal, Estonia, Morocco, Belgium, Vietnam, Canada, Jordan, Libya, Kuwait, Egypt, Morocco, Yemen, Bahrain, Tunisia, Sudan, Oman, Algeria, Saudi Arabia, Iraq, UAE, etc.

|

|

|

For more information about crankshaft inspection on site, inspection of Crankshaft of MAN Engine, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.