RA Power Solutions is engaged in the repair of crankshafts onsite up to a diameter of 700 mm of crankpin and main journal. We have experienced that in the case of Caterpillar, Cummins, Daihatsu, Yanmar, etc. auxiliary engines have medium or high RPM which makes the engine compact.

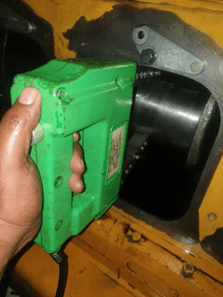

RA Power Solutions has expertise in the repair/grinding of crankshaft of auxiliary engines having small diameters and bearing widths. This is possible because the design of our crankshaft grinding machine is compact and can be easily placed on a crankpin diameter from the inspection window of the entablature. We have recently undertaken the grinding of Caterpillar engine model 3416B in Dubai.

The Engine and crankshaft details of Caterpillar 3416B are given below:

| S. NO | Crankshaft Details | |

| 1. | Engine Make | Caterpillar |

| 2. | Engine Model | 3416B |

| 3. | Crankpin Diameter Standard | 135 mm |

| 4. | Crankpin Bearing Width | 57 mm |

| 5. | Place of Execution of Job | Dubai Port |

A reputed shipping company based in Dubai had a problem with the crankshaft of Caterpillar 3416B. Our two technicians boarded the vessel on the same day and inspected the three crankpins that were damaged.

The crankpin dimensions were observed as follows crankpin no. 5,6 & 7.

The report is pasted below:

| SIZE OF CR JOURNAL BEFORE GRINDING (SIZES IN MM) | |||||||||

| A | Aa | C | Cc | B | Bb | Min | STD | Ovality | |

| CR-5 A bank | 134.72 | 134.95 | 134.76 | 134.95 | 134.85 | 134.96 | 134.72 | 135 | 0.28mm |

| CR-5 B bank | 134.85 | 134.96 | 134.77 | 134.96 | 134.80 | 134.96 | 134.77 | 135 | 0.23mm |

| CR-6 A bank | 134.66 | 134.94 | 134.65 | 134.95 | 134.67 | 134.95 | 134.65 | 135 | 0.35mm |

| CR-6 B bank | 134.67 | 134.95 | 134.73 | 134.96 | 134.72 | 134.95 | 134.67 | 135 | 0.33mm |

| CR-7 A bank | 134.72 | 134.96 | 134.71 | 134.92 | 134.78 | 134.95 | 134.71 | 135 | 0.29mm |

| CR-7 B bank | 134.78 | 134.95 | 134.77 | 134.95 | 134.82 | 134.97 | 134.77 | 135 | 0.23mm |

- The damaged crankpins were also subject to a high-intensity magnaflux test for crack. No crack or abnormality was observed.

- Other important parameters like hardness, deflection, and runout were observed within the limit as described in the Caterpillar maintenance manual.

- The grinding of the three crankpins was undertaken by our technicians and was finished in 48 hrs.

The final reading after the repair of the crankpin is given below:

| SIZE OF CR JOURNAL AFTER GRINDING (SIZES IN MM) | |||||||||

| A | Aa | C | Cc | B | Bb | Min | STD | Ovality | |

| CR-5 A bank | 134.36 | 134.37 | 134.35 | 134.36 | 134.36 | 134.37 | 134.35 | 134.37 | 0.02 mm |

| CR-5 B bank | 134.37 | 134.37 | 134.36 | 134.35 | 134.36 | 134.36 | 134.35 | 134.37 | 0.02 mm |

| CR-6 A bank | 134.37 | 134.36 | 134.36 | 134.35 | 134.36 | 134.37 | 134.35 | 134.37 | 0.02 mm |

| CR-6 B bank | 134.36 | 134.36 | 134.35 | 134.36 | 134.37 | 134.36 | 134.35 | 134.37 | 0.02 mm |

| CR-7 A bank | 134.37 | 134.36 | 134.36 | 134.37 | 134.36 | 134.35 | 134.35 | 134.37 | 0.02 mm |

| CR-7 B bank | 134.36 | 134.36 | 134.37 | 134.36 | 134.35 | 134.36 | 134.35 | 134.37 | 0.02 mm |

Repair expertise of RA Power Solutions in Caterpillar, Yanmar, Cummins, and Daihatsu high RPM engines

- In the case of Caterpillar model 3416B the standard diameter of the crank pin is 135 mm and the bearing width is only 57 mm. This needs a specially designed and dedicated onsite crankshaft grinding machine which has been developed by RA Power Solutions.

- No other company in the world, to our knowledge, has the capability of repairing the crankpin and main journal with a small bearing width, such as the Caterpillar model 3416B, which has a bearing width of only 57 mm.

We have been regularly executing the on site crankshaft repairs and crankshaft grinding in Antigua and Barbuda, Belize, Dominica, Dominican Republic, Grenada, Guyana, Haiti, Jamaica, Saint Kitts and Nevis, Saint Lucia, Saint Vincent and the Grenadines, Trinidad, and Tobago, etc.

For more details on the crank pin grinding repair please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.