It is generally observed that the companies based in Europe and Singapore do not have the necessary technology and equipment to undertake crankpin grinding and crankpin polishing of small diameters ranging from 70 mm to 180 mm, having a bearing width of as low as 50 mm. The companies do not have availability of the equipment can undertake the grinding and polishing of the crankpin and main journal having small diameters and less bearing width.

RA Power Solutions is the only company in the world that designs and manufactures onsite crankshaft grinding machines ranging from 35 mm to 700 mm in terms of diameter. The design and manufacturing of crankshaft grinding equipment for small diameters and with hands-on expertise, facilities, and experience is done by us. We were recently approached by one of our clients regarding the failure of YANMAR Diesel Engine 6N18AL-DV 450 kva. crankshaft.

The crankshaft’s major details are as follows

| S. NO | Crankshaft Details | |

| 1. | Engine Make | YANMAR Diesel Engine |

| 2. | Engine Model | 6N18AL-DV 450 kva |

| 3. | Crankpin Diameter Standard | 145 mm |

| 4. | Crankpin Bearing Width | 65 mm |

| 5. | Name of Vessel | MV MAITHIL |

As we can see from the above table YANMAR Diesel Engine 6N18AL-DV 450 kva has a crankpin diameter of 145 mm and a bearing width of only 65 mm.

The team of RA Power Solutions technicians was sent on board the vessel which was sailing near the SUEZ canal on-boarding the vessel, the inspection of the crankshaft was conducted, and the following observations were made.

- All the crankpins having a diameter of 145 mm and bearing width of only 65 mm had bearing line marks, pitting, taper, and ovality ranging from 0.16 to 0.28.

- The crankpin hardness and crack detection by MPI were done and no abnormality was observed.

- The deflection readings were observed within limits.

- It was decided to undertake the grinding of all the crankpins to the next undersize of 0.40 mm. All the crankpin diameter was maintained at 144.60 mm.

- The engine was assembled and load trials were taken.

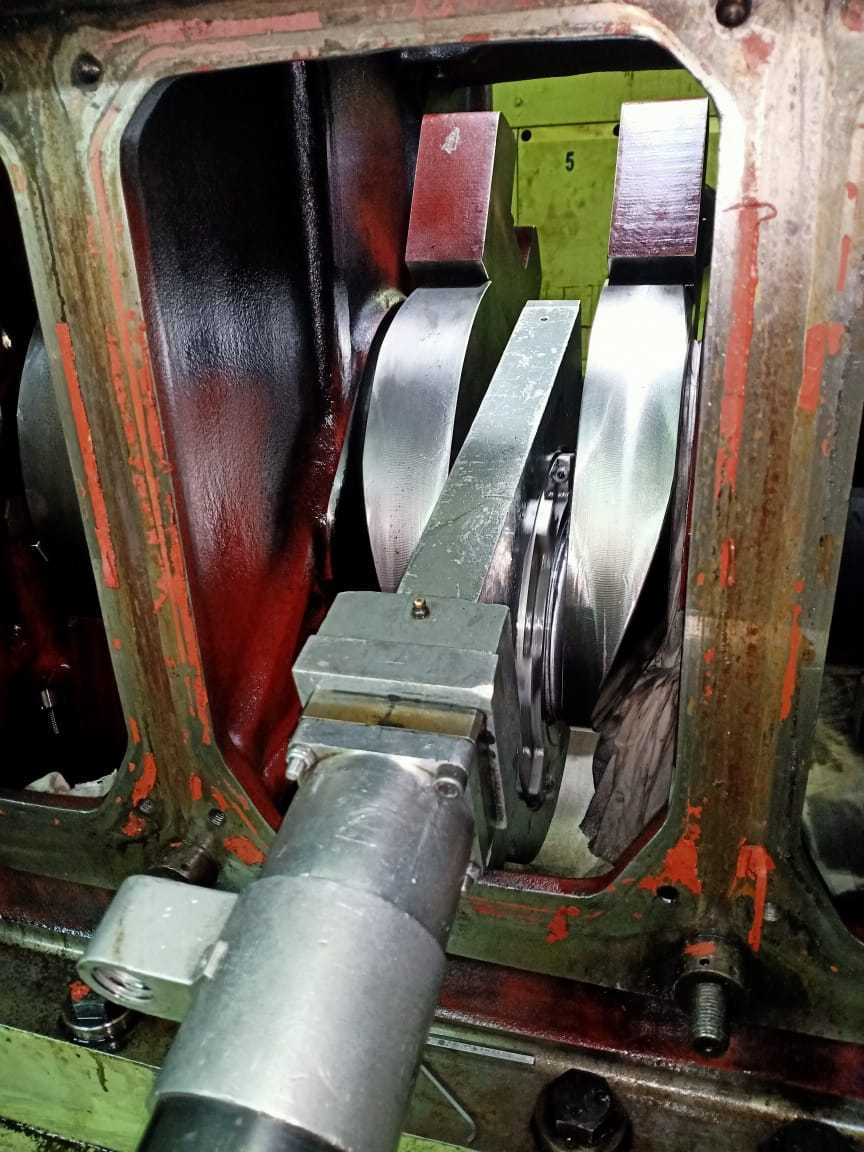

Successful crankshaft grinding and crankshaft polishing of Yanmar diesel engine 6N18AL-DV 450 kva.

The machine manufactured by us is designed to be accommodated on the crankpin diameter and is capable of maintaining the tolerance within 0.02 mm. To our knowledge, none of the crankshaft grinding companies possess compact equipment. For your requirement of grinding of crankshafts of small diameter and bearing width contact RA Power Solutions.

This blog is written by Mr. Raj Shahani (Managing Director of RA Power Solutions). He has more than forty years of experience in the field of engine repair and is a technical adviser to various shipping and heavy industries based all over the world. For more information, about the Yanmar diesel engine and repair of the diesel crankshaft, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.