Crankshaft Grinding Services in Dubai By RA Power Solutions

RA Power Solutions having experience of more than four decades has emerged as a leader in providing services for crankshaft grinding repair, onsite crankshaft grinding repair and in situ crankshaft grinding repair services in Dubai. We are based in New Delhi, India undertaking crankshaft grinding, crankshaft machining for the last 40 years.

The company is extending 24/7 emergency service for the repair of the crankshaft of main & auxiliary engines on board a vessel or for land-based installations. We have developed onsite portable, lightweight crankshaft grinding machines up to the diameter of 700 mm which are kept ready all the time to be taken on the vessel or to any diesel engine installation.

The titanium alloy used to make the crankshaft grinding machine, which is used for crankshaft repair, absorbs vibrations and makes it easier to maintain a tight tolerance of 20 to 30 microns. RA Power Solutions is the world leader in onsite crankshaft grinding repair and offer crankshaft grinding repair services at the lowest price with international standard. All of the crankshaft grinding and repairs we handle come with a performance guarantee.

Onsite Crankshaft Grinding Repair Services in Dubai

We perform onsite crankshaft grinding repair, crankpin reconditioning, and crankpin machining up to a diameter of 700 mm. It is observed that due to serious accidents sometimes the radius fillet of the main journal or crankpin is damaged & it is very difficult to perform the crankshaft repair on-site without removing the crankshaft from the engine block & transporting it to the designated workshop.

In Situ Crankshaft Machining And Grinding Repair Services in Dubai

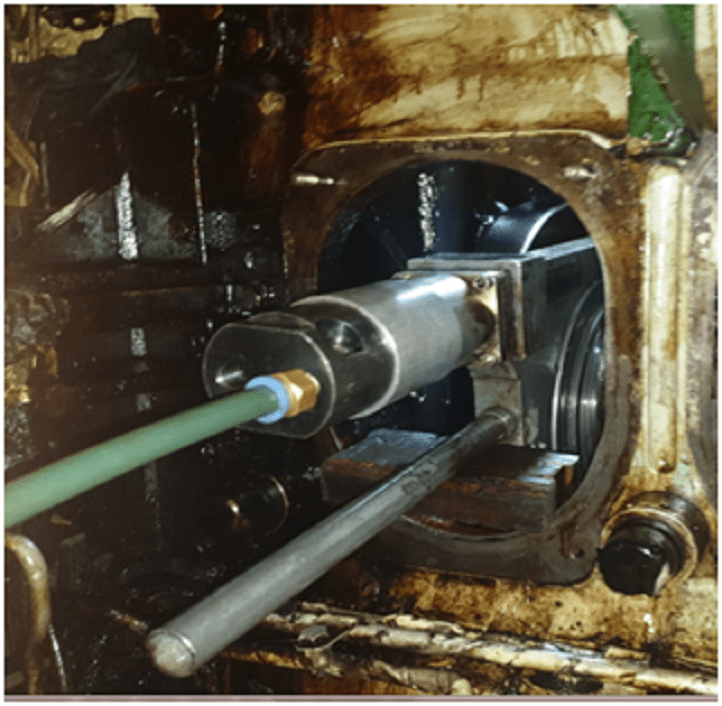

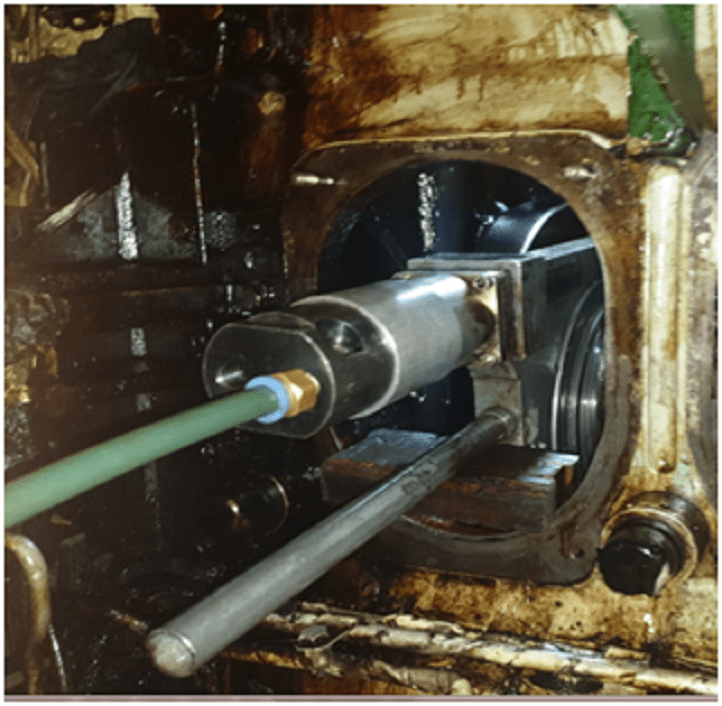

Crankpin repair by in situ crankshaft grinding machine is offered by us via a highly motivated professional team of technicians who have the experience of four decades in crankshaft grinding and repair. It is necessary that the crankshaft be initially inspected by trained and professional technicians in order to detect the fault after the damage or accident.

The following are the major parameters that are examined before the repair of the crankshaft:

- The minimum and maximum diameter of the crankpin & main journal, taper, and ovality is checked.

- Run out of main journals & deflection readings are taken to verify the loss of alignment.

- A complete nondestructive test using MPI & ultraviolet lamp for heat cracks is embarked of crankpins & the main journal of the crankshaft.

- The crankshaft is also subject to a hardness test.

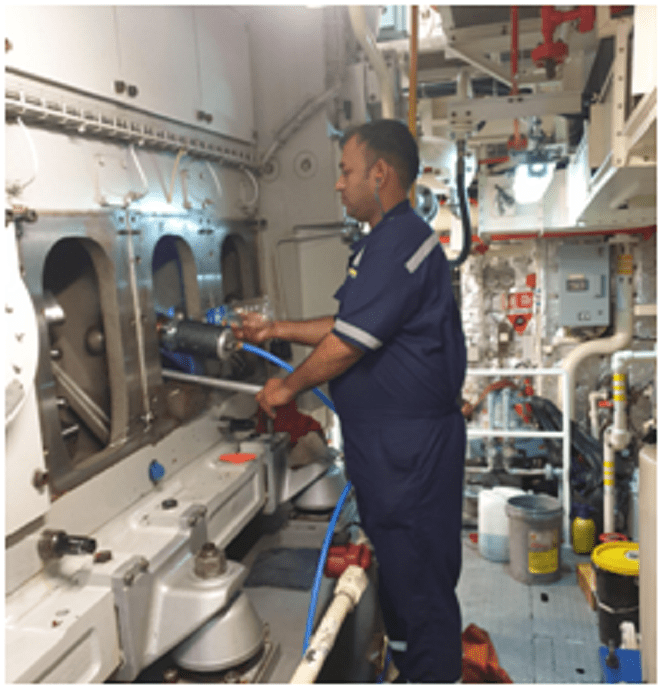

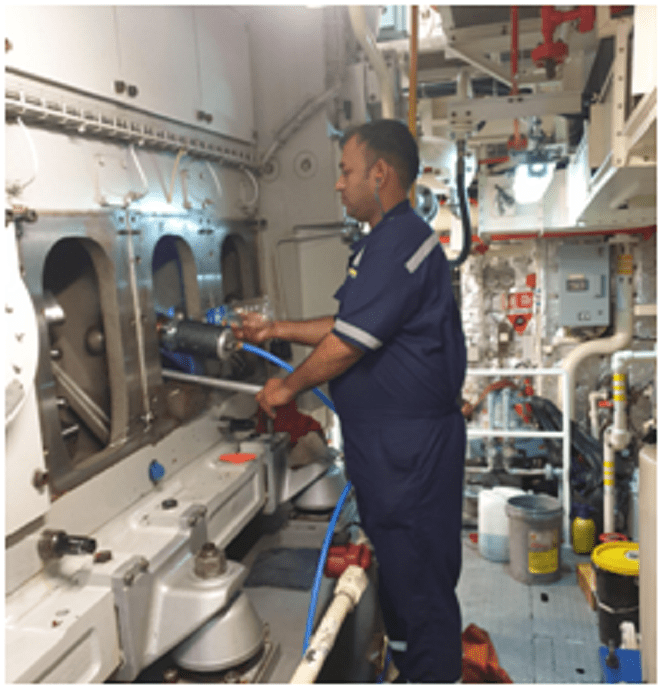

Based on the preliminary inspection reports prepared by our technicians the repair process is planned. The onsite crankshaft grinding machine used for the crankshaft repair is lightweight & is placed on the damaged crank pin from the inspection window of the engine block. It is not necessary to remove the crankshaft from the entablature & send it to the workshop as bench-type grinders are now outdated.

Our scope of work includes the following:

- Crankshaft, Crankpin Repair

- Crankshaft Journal Repair

- Crankshaft Repair

- Crankshaft Straightening

- Crankshaft Regrinding

- Crankshaft Polishing

- Crankpin Machining

- Crankshaft Journal Machining

We are commonly working on the following engines:

Wartsila, Daihatsu, Mirrless Blackstone, Yanmar, Allen, MAK, MAN, B&W, Sulzer, Caterpillar, Fiat, Mitsubishi, MTU, Cummins, Deutz, Nohab Polar, Wartsila 12V32, Wartsila 18V32, Pielstick, Bergen , Detroit Diesel, MaK 552 , MaK 453 , MaK 451 AK, Niigata, MaK 452 AK, Ruston, Lister Blackstone K8 Major MK2, Volvo Penta, etc.

RA Power Solutions works 24*7, 365 days a year to resolve each and every high-capacity engine-related problem. You can talk to our online representative at any time, please email us at rajshahani@rapowersolutions.

Telephone No.+91 9582647131