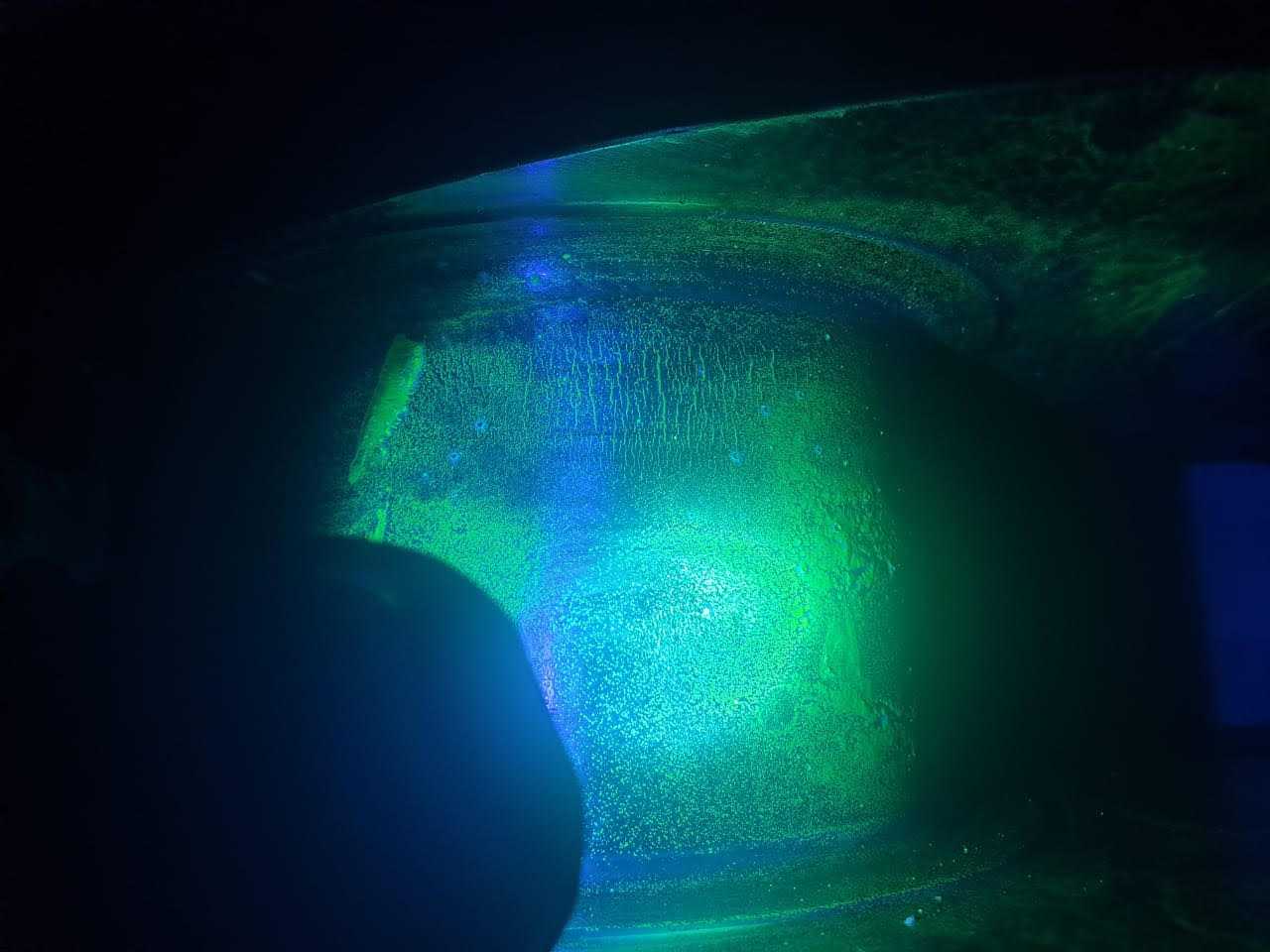

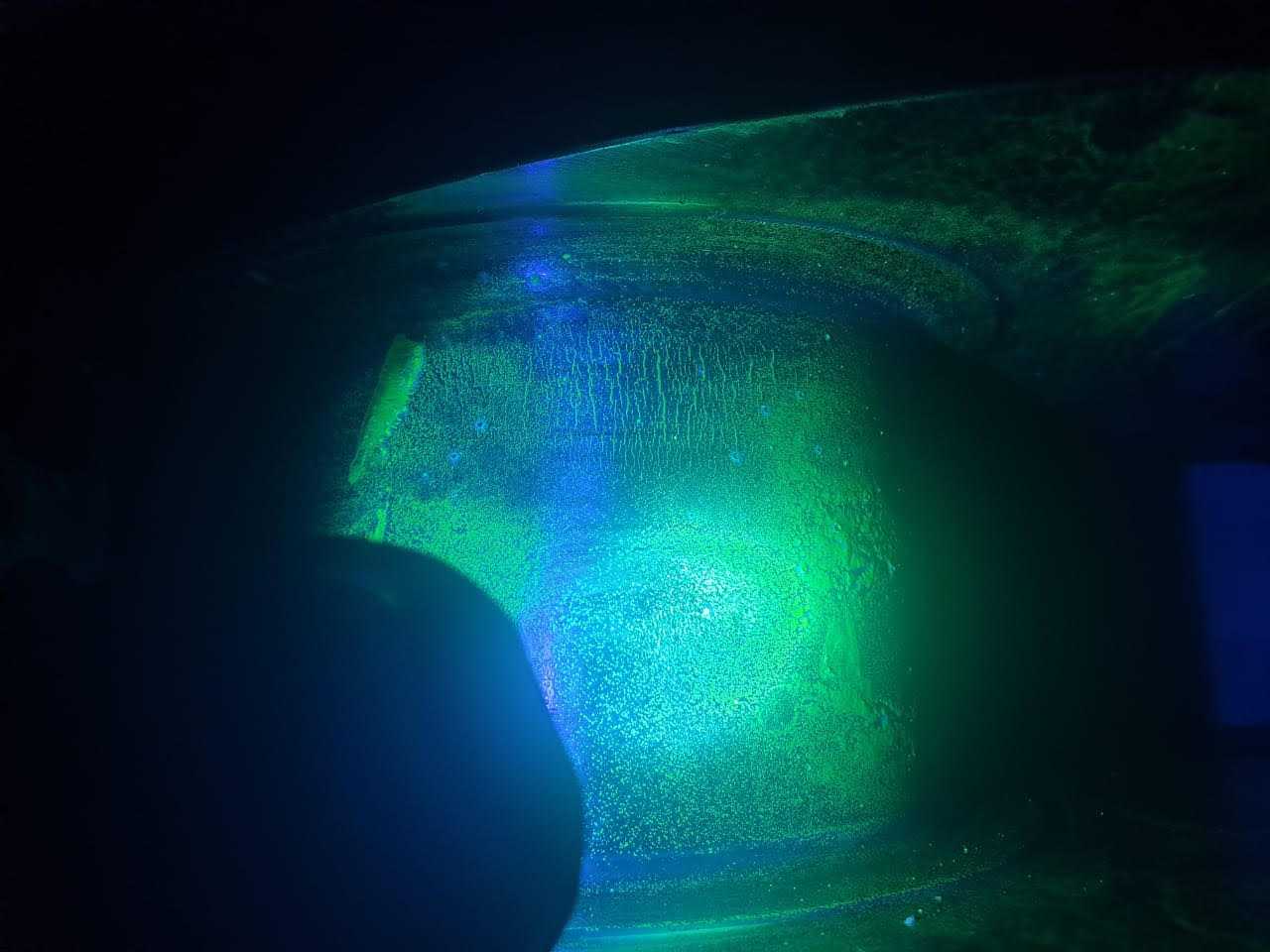

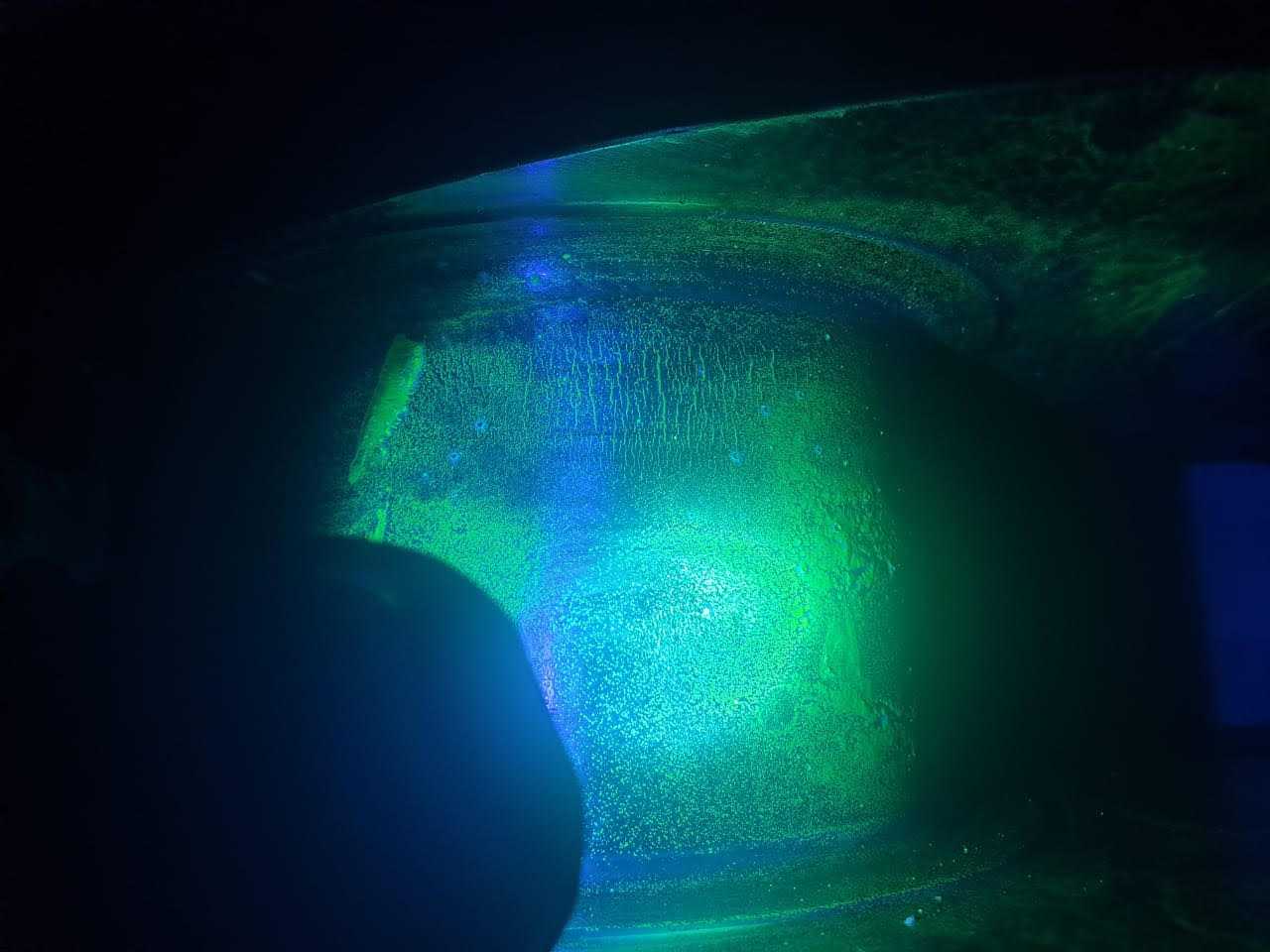

Compressor crankshafts due to continuous running, poor maintenance and working condition, and normal wear and tear require polishing and grinding. RA Power Solutions is the world’s leading company with 43 years of rich experience in the field of compressor crankshaft repair and extends on-site services all over the world.

We work on all types of Compressor Crankshafts including the following

- Axial Compressor

- Screw Compressor

- Centrifugal Compressor

- Turbo Compressor

- Reciprocating Compressor

The above compressors are in operation all over the world for a wide range of applications in industries, oil and gas sector, textiles, chemical companies, etc.

We extend services related to the Polishing and Grinding of Compressor Crankshaft maintaining the following major parameters and tolerances.

- On site compressor crankshafts are repaired by RA Power Solutions of diameter ranging from 30 mm to 700 mm.

- No requirement of removing the crankshaft from the compressor casing or body.

- The grinding of the compressor crankshaft and repair are undertaken without the disassembly of the main equipment.

- The use of modern, state of art compressor crankshaft grinding machines can deliver tolerances in terms of taper and ovality within 0.02 mm with a surface finish of 0.20 Ra value or even less depending on the compressor manufacturer’s requirement.

- Any length of compressor crankshafts can be repaired on-site.

- Stop sending the crankshaft of the compressor to the workshop for repairs which requires tremendous efforts to remove of compressor shaft from the main body, pack it, and send it to the workshop.

- Accidental repairs are undertaken on priority by senior engineers and technicians employed by us on a 24/7 basis.

Compressor shaft requires service with passion

- Our team of technicians is dedicated and works with all sincerity only with one motto of putting the compressors and main equipment in operation in the minimum possible time.

- The team is geared up to work non-stop, 24 x 7 hours to deliver the desired quality and results.

Specialized Compressor Crankshaft Repair equipment Used by RA Power Solutions

- We design and manufacture the on site compressor crankshaft grinding and repair equipment in technical collaboration with the world’s leading crankshaft grinding machine manufacturer based in Italy and undertake modifications in our compressor crankshaft grinding equipment in case of availability of limited space or any other restriction.

- Our technicians are trained in our in-house training school where we undertake serious damage jobs and extend the job training to our technicians.

Availability of Compressor White Metal Babbitt Bearing and Tri Metal Bearing

Knowing the difficulty faced by our clients, we undertake regularly the Rebabbitting of metal bearings used in high-capacity compressors. We also manufacture new white metal Babbitt bearings for compressors as per the drawing or sample.

The Rebabbitting of old damaged bearings and manufacturing of new bearings is done with a great speed to reduce downtime. We also supply tri metal bearings used these days on compressor crankshafts with high RPM.

The undersize, special size, crank pin, and main journal bearings for most of the popular compressor models are available in stock or they are sourced through our principles based in Japan, Korea, and Europe.

We have been working on all models of compressors including Ariel, Cummins, Kirloskar, Samson, Porter-Cable, Stanley Bostitch, Campbell Hausfeld, DeWalt, Makita, Senco, ANEST IWATA, Gardner Denver, Graham Sulzer, Hitachi, Rolair Systems, Brehob, Lufkin, Zebra, Ingersoll Rand, etc

For more information on compressor shafts, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.