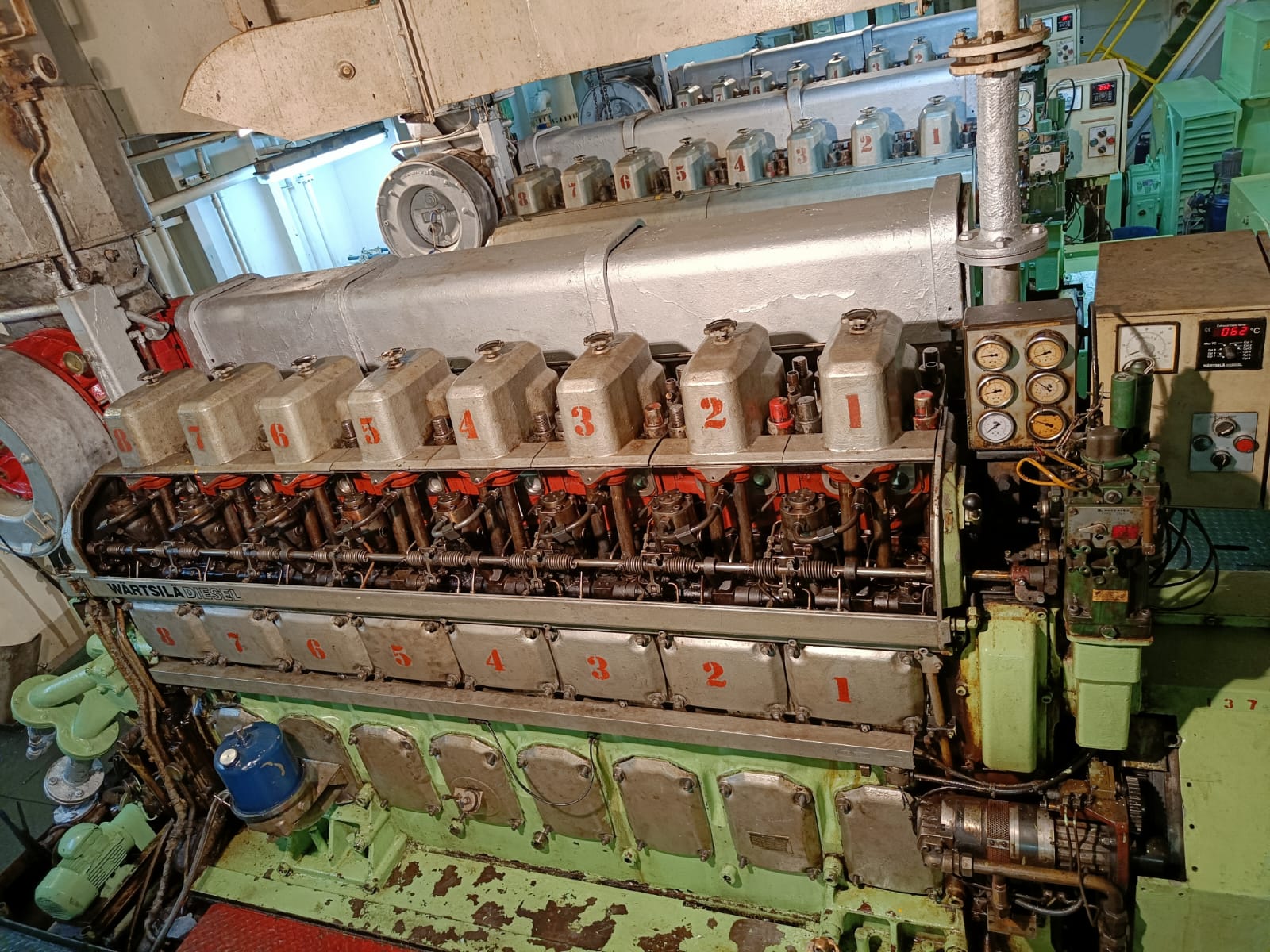

Wartsila 8L20 Auxiliary engine met with a serious accident, the damage of crankshaft was reported. RA Power Solutions team of two technicians along with onsite crankshaft grinding machine boarded the vessel at Lome Port, Togo. This was possible as all our technicians have valid Passport/Seaman Book/ USA VISA.

| Wartsila 8L20 having Damage Crankshaft | Damage CR Pin of Wartsila 8L20 Engine |

|

|

We have a team of trained technicians available 24/7 hrs.

Inspection of the crankshaft of Wartsila 8L20 and Observation

- On Initial inspection of the crankshaft it was found that the crankpin number #05 was damaged.

- On further investigation our technicians were surprised to note that the crankpin having standard diameter of 180 MM was already undersized by 2.00 MM and this job was done by a company based in Greece.

- The excessive taper was observed on the crankpin and no radius fillet profile was made by the crankshaft repair company.

- Due to the taper in the crankpin number #05 of the wartsila 8L20 crankshaft, the connecting rod was not moving freely and the bearing was developing line marks.

- It was a challenging job for RA Power Solutions technicians to rectify the taper, which was developed due to application of wrong equipment and process by a company based in Greece.

| Crack Detection of CR Pin with MPI | Deep Scoring Marks on CR Pin |

|

|

Action Taken By RA Power Solutions to Successfully Repair Wartsila 8L20 Crankshaft and To Save it from Rejection

With our experience of more than 44 Years in repair of the crankshaft, latest design of equipment, and experienced technicians, we were able to successfully repair the crankshaft by under-sizing the crank pin and maintaining the final size of 177.00 MM. The crank pin was undersized by 3.0 mm.

| CR Pin Grinding Under Process | Polishing of CR Pin after Onsite Grinding |

|

|

The radius fillet profile of both the sides was prepared and maintained, as per the Wartsila 8L20 specifications stipulated in the maintenance manual.

The engine was commissioned in presence of our technicians and performance was found satisfactory.

For more information regarding crankshaft grinding services, and onsite crankshaft repair services, please contact us at rajshahani@rapowersolutions.com or info@rapowersolutions.com or call us at +91 9582647131 or +91 9810012383.

| Final Polishing of CR Pin | CR Pin after grinding & Polishing |

|

|