RA Power Solutions was approached by a shipping company based in Kuwait regarding a problem faced by them in the auxiliary engine of Wartsila 4L20, It was reported that the crankpin bearings are failing repeatedly. The vessel was to take birth at Chennai, an Indian port.

The significant technical details of the crankshaft of Wartsila 4L20 are as follows:

| S.No. | Crankshaft Details | |

| 1. | Engine Make | Wartsila |

| 2. | Engine Model | 4L20 |

| 3. | Crank pin Diameter Standard | 180 mm |

| 4. | Crankpin Bearing Width | 71 mm |

| 5. | Main journal diameter | 210 mm |

| 6. | Place of execution of crankshaft repair | At Port Chennai |

The following are the main observations on the crankshaft of Wartsila 4L20 by our technicians:

- Our two technicians boarded the vessel at Chennai port and inspected the crankshaft in which repeated failure of crankpin bearings was reported.

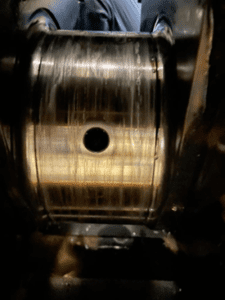

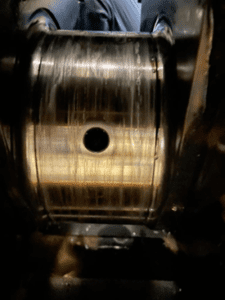

- After removing the connecting rods all four crankpins were subject to the following inspection:

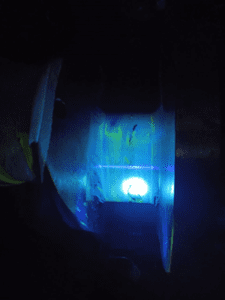

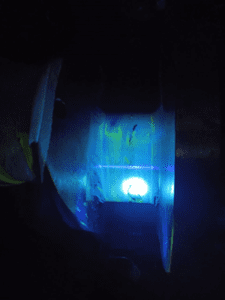

- Crankpins of Wartsila 4L20 engine crankshaft were subject to a hardness test and hardness was observed within the range of 260 to 290 on the HB scale. The crack detection was undertaken of all the crankpins by magnaflux torch and no cracks were observed.

- As a matter of routine, our technicians also checked the deflection of the crankshaft and were observed within limits.

- During the dimensional inspection of the crankpin, excessive ovality was observed against the standard diameter of 180 mm. The crankpin diameter was observed ranging between 179.60 mm to 180.00 mm.

The crank pin readings before grinding are mentioned below:

| STANDARD/SPECIFIED NO. SIZES IN MM. | |||||||||

| SIZE OF CR BEFORE GRINDING | |||||||||

|

|

A | Aa | C | Cc | B | Bb | Min | STD | Ovality |

| CR-1 | 179.73 | 179.92 | 179.74 | 179.91 | 179.71 | 179.93 | 179.71 | 180.00 | 0.29 mm |

| CR-2 | 179.60 | 179.80 | 179.61 | 179.82 | 179.78 | 179.88 | 179.60 | 180.00 | 0.40 mm |

| CR-3 | 179.66 | 179.84 | 179.70 | 179.84 | 179.75 | 179.90 | 179.66 | 180.00 | 0.34 mm |

| CR-4 | 179.71 | 179.89 | 179.70 | 179.71 | 179.92 | 179.85 | 179.70 | 180.00 | 0.30 mm |

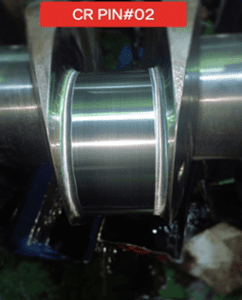

- Considering the above readings of taper & ovality it was decided to undertake the grinding of all four crankpins of Wartsila 4L20 engine crankshaft. In the case of this crankshaft the crankpin bearing width is minimal i.e. 71 mm only.

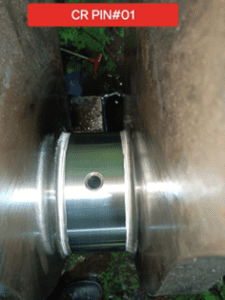

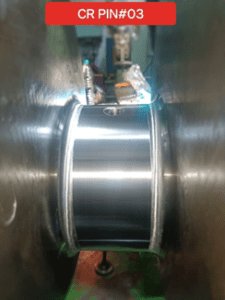

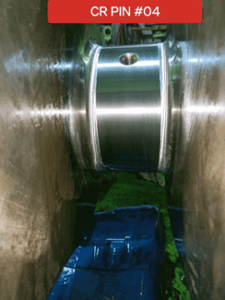

- RA Power Solutions technicians carried with them a special-purpose crankshaft grinding equipment tool that can be inserted on the crank pin diameter from the inspection window.

- The grinding of all four crankpins was undertaken and the diameter of the crankpin was maintained between 179.48 mm to 179.50 mm.

- The reading of the final dimensions after grinding are pasted below:

| STANDARD/SPECIFIED NO. SIZES IN MM | |||||||||

| SIZE OF CR AFTER GRINDING | |||||||||

|

|

A | Aa | C | Cc | B | Bb | Min | STD | Ovality |

| CR-1 | 179.50 | 179.48 | 179.49 | 179.50 | 179.48 | 179.49 | 179.48 | 179.50 | 0.02 mm |

| CR-2 | 179.49 | 179.48 | 179.48 | 179.50 | 179.48 | 179.49 | 179.48 | 179.50 | 0.02 mm |

| CR-3 | 179.48 | 179.49 | 179.49 | 179.48 | 179.50 | 179.50 | 179.48 | 179.50 | 0.02 mm |

| CR-4 | 179.49 | 179.50 | 179.50 | 179.48 | 179.49 | 179.49 | 179.48 | 179.50 | 0.02 mm |

Achievement of RA Power Solutions technicians in the successful repair of the crankshaft of the Wartsila 4L20 engine

- The onsite grinding of crankpins of the Wartsila 4L20 engine is complicated because the crankpins’ width is only 71 mm further the counterweights are positioned in such a way that it is difficult to insert the onsite crankshaft grinding machine.

- Most of the companies based in Europe, Singapore, and worldwide do not have the tooling to undertake the grinding of the crankpins of Wartsila 4L20 due to their complicated design and small bearing width of 71 mm only.

- RA Power Solutions with an experience of forty-three years in onsite repair of crankshaft is also the manufacturer and largest seller of onsite crankshaft grinding machines in the world.

- As a manufacturer, we design the equipment according to the site requirements resulting in the successful repair of the crankshaft. Ours is the only company in the world that can undertake the grinding while sailing the vessel.

- We undertake onsite repair of the crankshaft of 700 mm diameter including Wartsila engines like 8L20, R22H,824TS,12V32,16v32, L32, ZAV 40, 6ZLA 40 etc.

RA Power Solutions has been extending onsite crankshaft repair services for the last more than four decades. All our technicians carry seaman books and can fly to any destination in the world quickly. We carry the grinding machine and tooling as accompanying baggage which saves time. Few of our technicians also possess American VISA and can travel to South America, the Caribbean, etc.

We have been regularly executing the repairs in Madagascar, Oman, Qatar, Philippines, Bahrain, Srilanka, Bangladesh, Myanmar, Turkey, Nigeria, Greece, Saudi Arabia, UK, Dubai, Malta, Cyprus, Singapore, Malaysia, Colombia, Indonesia, Hong Kong, Spain, Netherlands, Dubai, Portugal, Estonia, Morocco, Belgium, Vietnam, Canada, Jordan, Libya, Kuwait, Egypt, Morocco, Yemen, Bahrain, Tunisia, Sudan, Oman, Algeria, UAE, Iraq.

For more information on crankshaft grinding equipment, Wartsila Engine Crankshaft Grinding, and Wartsila Engine Crankshaft 4L20 Repair On Vessel, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.