Wartsila engine 8L32 Crankshaft has been successfully repaired by RA Power Solutions technicians on board a vessel. In fact, due to commitment to the movement of the container vessel by the owners, one number crankpin of Wartsila Engine 8L32 was repaired while sailing the vessel between Port Khorfakkan Sharjah UAE to Iran Port.

The detail of the Wartsila engine 8L32 crankshaft are as following:

| S.No. | Crankshaft Details | |

| 1. | Engine Make | Wartsila |

| 2. | Engine Model | 8L32 |

| 3. | Crankpin Diameter Standard | 310 mm |

| 4. | Crankpin Bearing Width | 105 mm |

| 5. | Place of execution of crankshaft repair | Sailing from Khorfakkan Port Sharjah UAE to Iran Port |

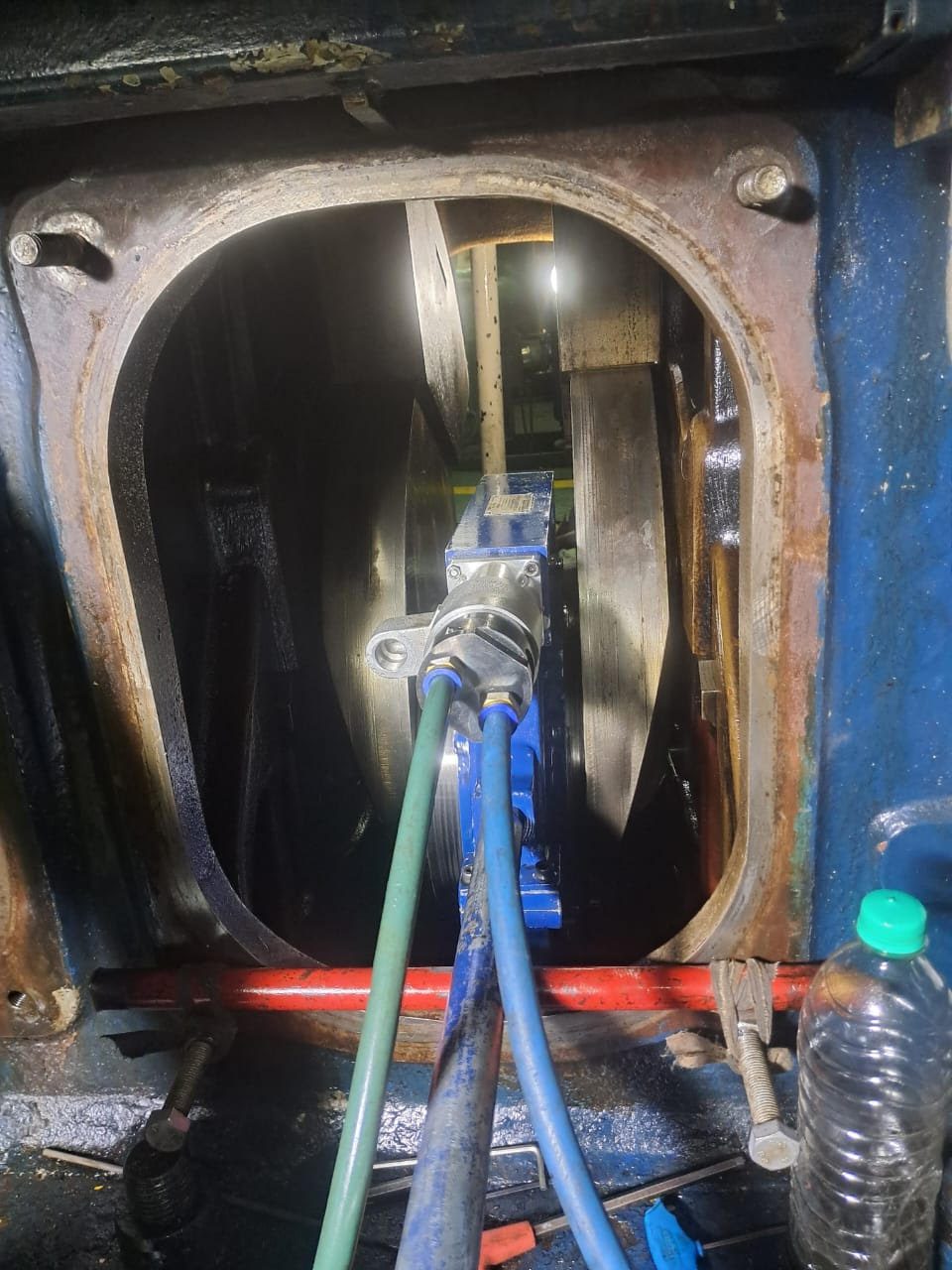

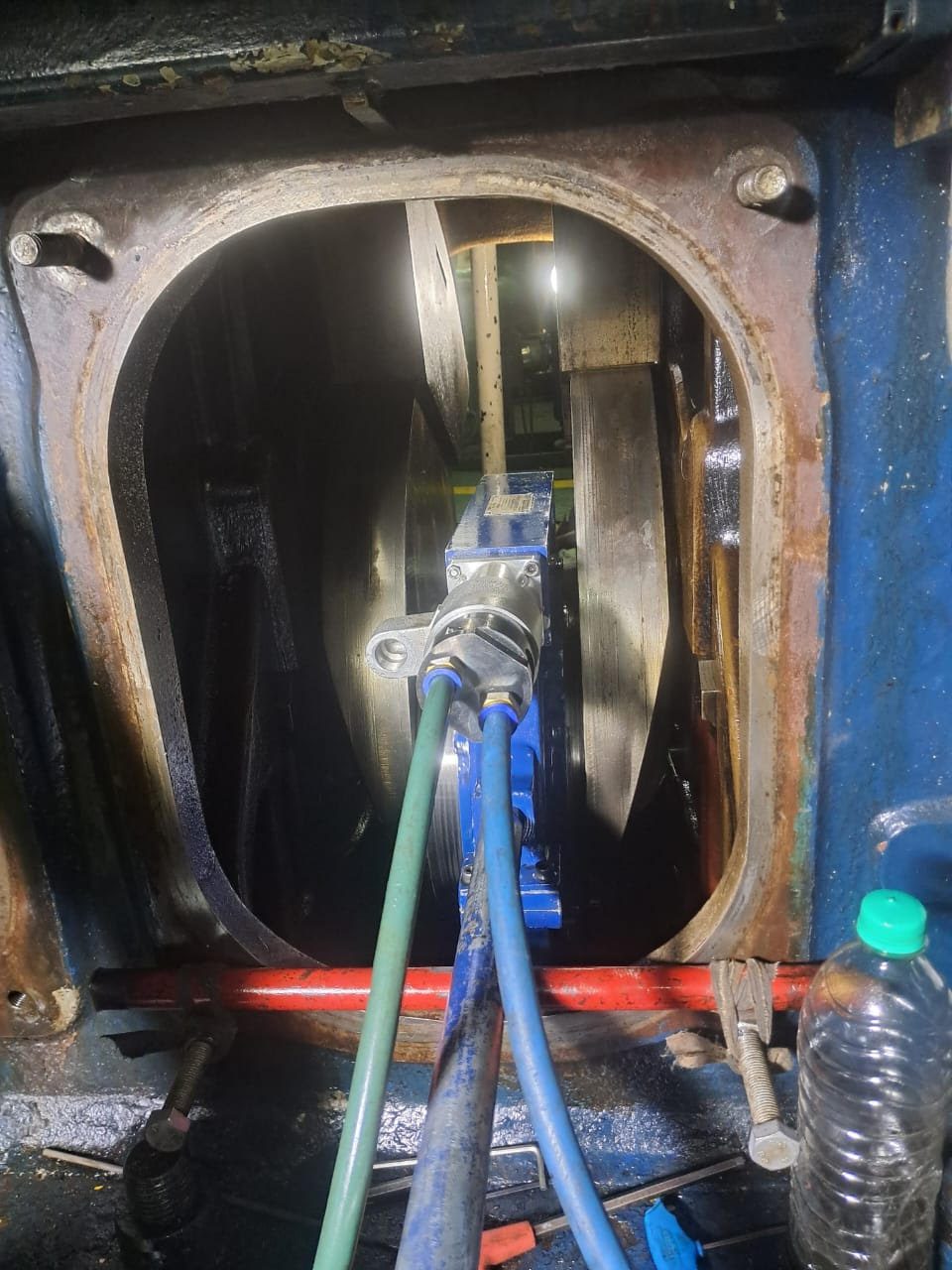

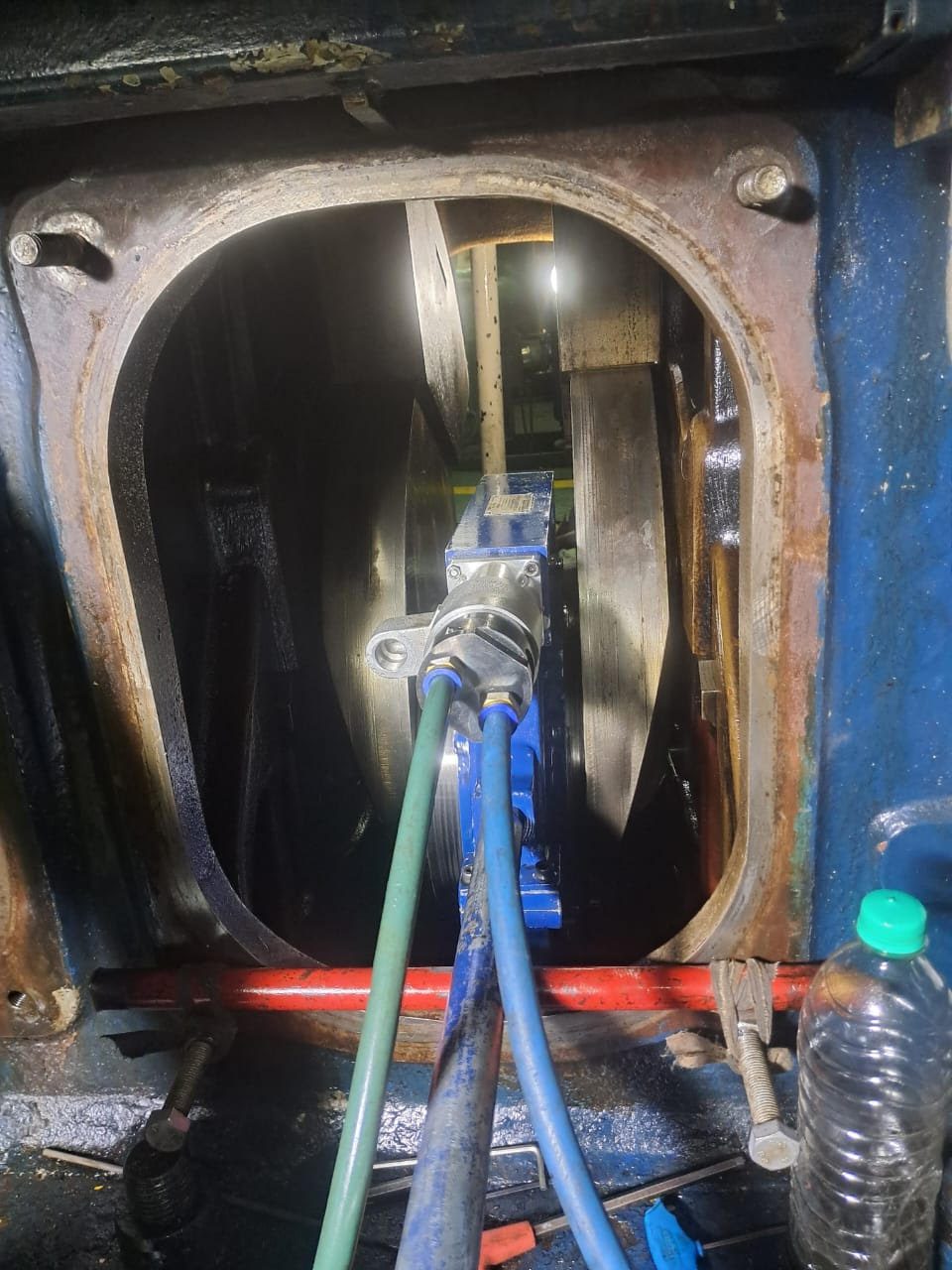

The damage to the crankshaft of Wartsila Engine 8L32 was reported by the owners. Two technicians of RA Power Solutions with an onsite crankshaft grinding machine boarded the vessel at Khorfakkan Port Sharjah UAE.

Following are the main observations after inspection of the damaged crankshaft.

- The crankpin no. 06 was found damaged with deep line marks and localized depression.

- During the dimensional inspection of the crankpin ovality of 0.18 mm was observed. The readings are pasted below:

| A | Aa | C | Cc | B | Bb | Min | Max | Ovality | |

| CR-1 | |||||||||

| CR-2 | |||||||||

| CR-3 | |||||||||

| CR-4 | |||||||||

| CR-5 | |||||||||

| CR-6 | 309.86 | 309.93 | 309.89 | 309.83 | 309.88 | 309.82 | 309.82 | 310.00 | 0.18 mm |

- Hardness was checked as per the procedure and was observed between 260 and 320 on the HB scale.

- Scattered high hardness spots up to 498 HB were observed.

- During the MPI test of the crankpin, no crack was observed.

Action taken by RA Power Solutions technicians to successfully repair the crankshaft of Wartsila Engine 8L32

- The grinding of crankpin no. 06 was initially undertaken to the undersize of 0.5 mm.

- During the joint inspection, a localized damage area was still present on the crank pin diameter. In this situation, it was jointly decided by RA Power Solutions technicians and the chief engineer to undertake the grinding to the next step size of 1.0 mm.

- The grinding was done to 1.0 mm undersize maintaining the ovality of 0.02 mm. The final dimensional report is pasted below:

| SIZE OF CR Pins | |||||||||

| A | Aa | C | Cc | B | Bb | Min | Max | Ovality | |

| CR-1 | |||||||||

| CR-2 | |||||||||

| CR-3 | |||||||||

| CR-4 | |||||||||

| CR-5 | |||||||||

| CR-6 | 309.00 | 308.99 | 308.99 | 308.99 | 309.00 | 309.01 | 308.99 | 309.01 | 0.02 mm |

- The radius fillet of both sides which was damaged was repaired successfully and polished.

- The complete repair of the Wartsila Engine 8L32 was successfully carried out during the sailing of the vessel from Khorfakkan Port Sharjah UAE to an Iran Port.

- Since a 1.0 mm undersize bearing was available on board the vessel. Our technicians assisted the ship staff in the assembly of the engine. The engine was commissioned in the presence of our technicians and performance was observed satisfactory.

RA Power Solutions has been undertaking crankshaft repair of all popular makes and models of engines for the last forty-three years. The Crankshafts of Wartsila models like 8L20, R22H, 824TS, 12V32, 16v32, L32, ZAV 40, 6ZLA 40 etc have been successfully repaired.

We have teams of trained technicians available 24/7 hrs. and can be deputed on short notice. Some of our technicians also have valid US VISA, and CDC and can fly to South America, Caribbean countries, etc. on short notice carrying on site crankshaft grinding equipment with them as accompanying baggage.

RA Power Solutions offers top-notch crank pin grinding services and vessel crankshaft repair solutions. With a commitment to precision and excellence, our experienced team ensures that crankshafts are meticulously restored to their optimal condition, enhancing the efficiency and longevity of marine vessels.

We have been regularly executing on site crankshaft repairs and crankshaft grinding in Dubai, Oman, Saudi Arabia, Qatar, Abu Dhabi, Sharjah, Ajman, Umm Al-Quwain, and Fujairah, Bahrain, Kuwait, Iraq, Antigua and Barbuda, Belize, Dominica, Dominican Republic, Grenada, Guyana, Haiti, Jamaica, Saint Kitts and Nevis, Saint Lucia, Saint Vincent and the Grenadines, Trinidad, and Tobago, etc.

For more details on the crank pin grinding repair, crank pin grinding services, and vessel crankshaft repair please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.